Other Parts Discussed in Thread: PMP21697,

Tool/software:

Hi,

We would appreciate any help understanding the LM5176 behavior in our implementation of a boost controller greatly inspired on the PMP21697 reference design.

Vi: 10-16V

Vo : 42V

Io : 8A max

Fsw : 140kHz

I would include the calculator but we had a lot of problems with the excel file.

Sch :

-> The boost converter works great at no and low loads (<2A out approx). At higher loads the switching becomes somewhat erratic and the inductor heats up quickly.

For debugging purposes, we removed the avg output current limiting and also the hiccup mode.

At no load SW2:

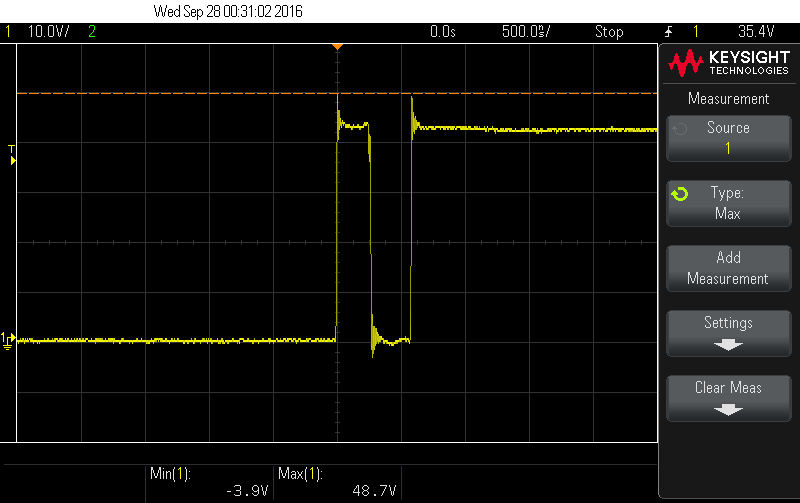

And with load exceeding 2A, SW2:

(I am glad I found the reference on this forum to measure using small ground pin on oscilloscope probe)

Any help understanding what is happening would be appreciated.

Also we have omitted the SW2 snubber leg on this design. Could this alone cause this erratic switching?

Regards,

Joseph.