Other Parts Discussed in Thread: EV2400, BQSTUDIO, BQ35100

Tool/software:

Hi, TI expert

Customer have some questions while testing BQ35100EVM-795.

First, I successfully ran bqStudio through BQ35100EVM and EV2400 to connect to the EVM board.

Next, I would like to conduct a test to measure the battery usage using EOS mode.

Q1) When using EOS mode, it seems that the usage is checked by measuring the change in the internal impedance value of the battery. Can you tell me the exact measurement method?

Q2) When setting the EOS mode and applying the NEW Batt setting, when should I run GUAGE_START and GUAGE_STOP?

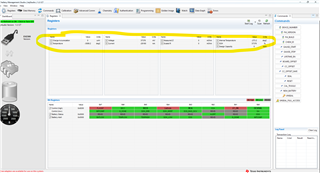

Q3) How can I check the actual measurement values (voltage, current, SOH, etc.) of BQ35100 in bqStudio?

Below are some questions customer have during the test.

4) Also, since bq35100 is for special batteries, can you explain how the current gauge and the general gauge for the battery used by the customer are different?

The battery is 3.6V and can be used up to 90%, and its capacity changes depending on temperature and current.

5) I wonder why BQ35100 came out for a specific battery, and does it compensate only for temperature or current?

6) There is no part that determines the total battery capacity, and can it just monitor the simple current amount? Can you tell me the exact mechanism?

Technical Spec of ER26500_C.PDF

Technical Spec of ER34615_D.PDF

Please check. Thank you.