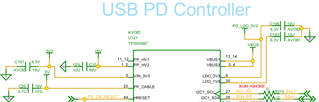

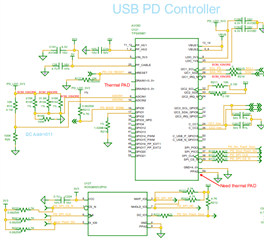

Other Parts Discussed in Thread: TPS65987, TPS25751, TPS65987D

Tool/software:

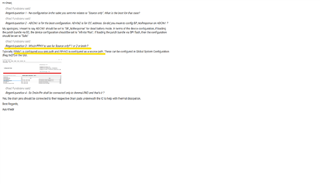

Hi Christofer,

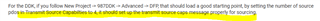

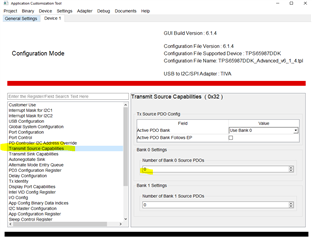

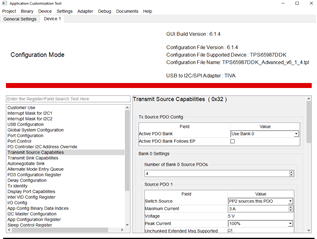

In continues to our conversation, you wrote me in the past that I can use any nominal programmer which use SPI interface for burning the PD controller TPS65987DDK.

Can you please confirm if the CH341A Programmer can burn image on TPS65987DDK PD Controller?

Thanks,

Ohad