Other Parts Discussed in Thread: BQ78350

Tool/software:

Dear TI Team,

We have been notified of existance of a IFC(Instruction Flash Checksum Failure ) in one of our e-bike product after a couple of usage in the field. This is the first time we faced with this failure , which is seen only at one product.

Upon this failure I have checked the following e2e threads from the forum.

- https://e2e.ti.com/support/power-management-group/power-management/f/power-management-forum/862688/bq78350-r1-bq78350-r1-manufactureraccess-0x0005-static-df-signature-failure/3192156?tisearch=e2e-sitesearch

- https://e2e.ti.com/support/power-management-group/power-management/f/power-management-forum/689090/bq78350-r1-permanent-fail-ifc-flag?tisearch=e2e-sitesearch&keymatch=bq78350%2520IFC#

- https://e2e.ti.com/support/power-management-group/power-management/f/power-management-forum/950431/bq78350-r1-flash-data-loss-corruption?tisearch=e2e-sitesearch&keymatch=bq78350%25252520IFC

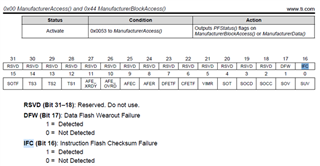

When I inspected the responses given to threads mentioned above , I saw that there has been an improvement in instruction flash checksum calculation in R2 gauge firmware. This change is cited from "bq78350-R1 TRM Addendum for the bq78350-R2 Device" at given responses. Before taking any action on devices at the field, we would like to take information about following questions.

- Has IFC failure seen randomly at BQ78350 products with R1 firmware? Is there any scenario that triggers IFC error more frequently besides reasons mentioned in previous threads?

- Is there a possibility for IFC error to occur at ideal implementation later? Could we ensure that IFC error will not occur in a product that has been used within defined limits with R1 firmware?

- Had IFC error seen in devices with R2 firmware given they operate within defined conditions? Will R2 gauge firmware update provide a certain solution to IFC error?

Information about Gauge IC , system status and logs taken from faulty system is listed below. This logs are read from Gauge IC by E-bike battery MCU and formatted accordingly.

Gauge Hardware : Bq78350_R1

Gauge Firmware Version : bq78350_R1_v1_04_build_26 1.srec

|

Permanent Failure |

0x10000 |

|

Protection |

0 |

|

Cell1 Voltage |

3917 |

|

Cell2 Voltage |

3913 |

|

Cell3 Voltage |

3919 |

|

Cell4 Voltage |

3921 |

|

Cell5 Voltage |

3922 |

|

Cell6 Voltage |

3911 |

|

Cell7 Voltage |

3919 |

|

Cell8 Voltage |

3917 |

|

Cell9 Voltage |

3916 |

|

Cell10 Voltage |

3907 |

|

Max Cell Temperature |

19 |

|

Min Cell Temperature |

8 |

|

FET temperature |

8 |

|

Current at PF |

0 |

|

Remaining Capacity |

0 |

|

Full Capacity |

9000 |

We would appreciate a fast response for our diagnosis , planning and informing processes. Thank you for your interest.