Other Parts Discussed in Thread: BQ40Z50

Tool/software:

Hello everyone,

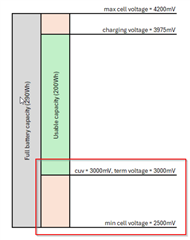

We are currently configuring a battery pack using the BQ40Z60. We have successfully completed the learning cycle using the same cells in our 160Wh battery pack. Now, we're making a new 200Wh battery pack with identical cells, but different voltage thresholds in order to achieve a different battery capacity.

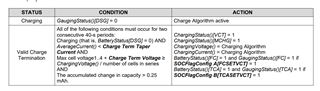

During cycle testing however, we are unable to get Qmax updates. The cycle count increments (the pack is currently at 7 cycles), but Qmax cycle count remains at 0 and Qmax does not change.

We've studied the Qmax update criteria from the datasheet and we don't think any of the four conditions apply. Can anyone help us out and tell us why Qmax updates are not occurring? I have attached the charge/discharge cycle logging and the device gg.csv files.