Part Number: BQ34Z100-R2

Tool/software:

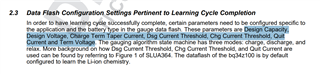

Hello,

I'm trying to use the GPC Golden GG Maker tool but I'm unable to get a valid report back with parameters that need to be updated. I used the GPC Chem tool to get a list of valid chemistry ID's for the cells we are using, and I've tried programming around 10 different ones but I'm still receiving the same errors each time. The errors that are coming up consistently are:

Warning: DODdifference before and after discharge less than 70% Qmax accuracy reduced:

Warning: Voltage under load 2021 mV is higher than OCV 2011mV. Please check correctness of your chem ID.

I've attached the CHEM-ID report, and the zip-file sent to the Golden GG Maker tool. Not sure why none of these chemistries are working, or why its seeing less than 70%DOD difference. If someone could take a look at my files to see where the problem is that would be great.

Thanks,

Jordan