Other Parts Discussed in Thread: EV2400

Tool/software:

Hello TI team,

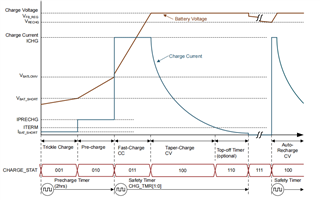

I have recently used your BQ25756E for charger PCB design, my circuit and PCB are attached. I tested it under pure resistor programming condition, DRV_SUP is powered by REGN and the load is CV load. Currently I encountered the following problem I hope to get your help:

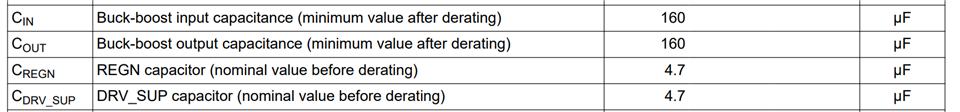

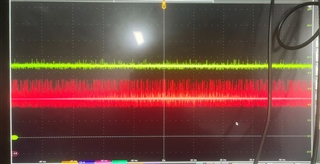

When I input a DC voltage with VIN of 6V and maximum 2A, VIN will generate intermittent oscillations (70Hz) causing the chip not to work properly, as shown in the red waveform below, I soldered a 4.7uF and 150uF capacitor on the input side and a 150uF capacitor on the output side at the moment. Is this problem caused by my capacitors being too small and how to fix it?

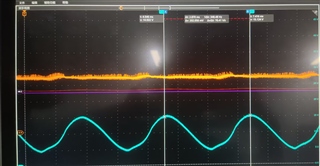

PS: When I use a power supply with less output power to input a DC current with a VIN of 5V and a maximum of 0.3A the chip shows normal operation with no large fluctuations in VIN.BQ25756E.rar

Thanks in advance!