Other Parts Discussed in Thread: LMQ66430,

Tool/software:

Hello,

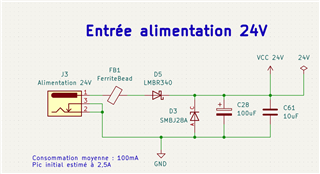

I'm having a problem with the TLVM 23615.

I use this component to convert 24V to 5V and 3.3V to power CPUs.

For 3 out of 5 boards I've had built don't work.

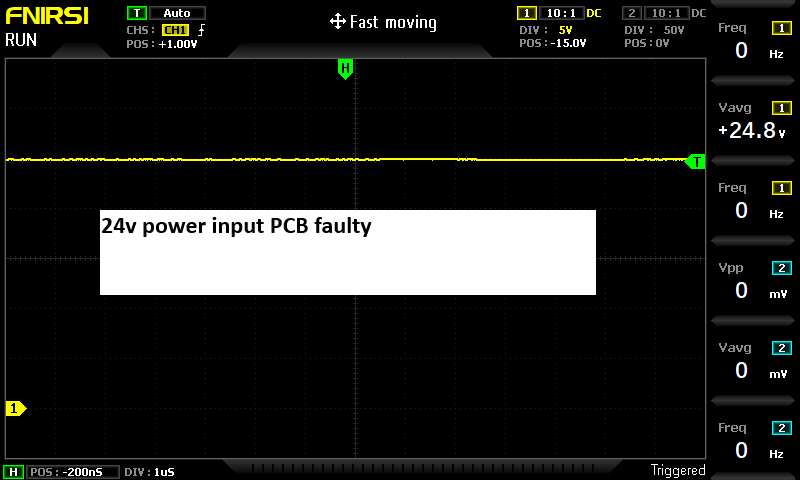

24V arrives correctly on VIN and EN, but the output voltage is 0.

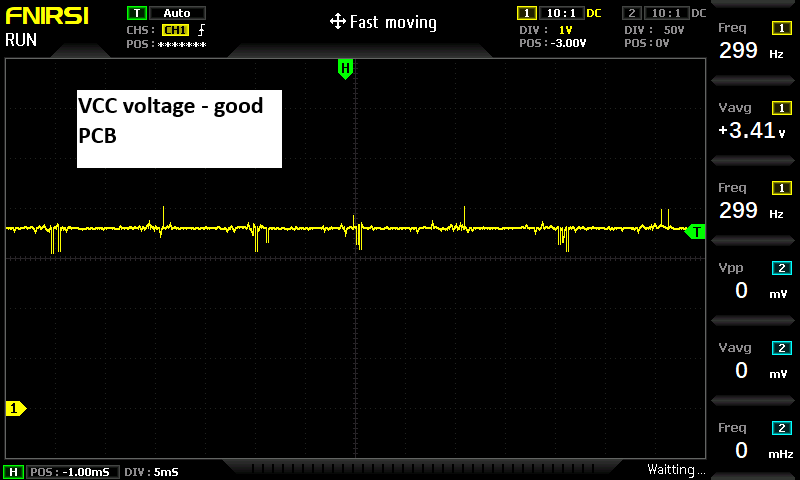

On 2 boards that work well, the output voltage is correct.

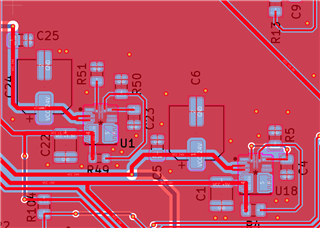

The schematic was designed by TI's tools.

So, it's a problem with the PCB design or the track layout, but I don't understand why.

Please help me. Any advice accepted!