Tool/software:

Hi

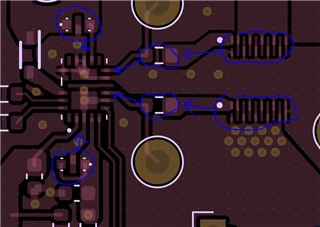

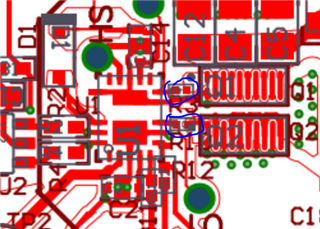

we are developing a GANFET based Buck converter using LMG1210 driver by following the LMG1210-EVM schematics and Layouts to Achieve optimal PCB inductance and less noise.

the Objective of the Board is to be Able to control the Buck Converter through a Raspberry Pi Pico PWM signals with Choice of Different Inductors for Testing Purposes.

We would like You to Review Our Layout and Provide valuable Feedback and Recommendations.

Below attached link is the Kicad Canvas of our Project, the Github of the Project files is also attached below

https://kicanvas.org/?github=https%3A%2F%2Fgithub.com%2Fsuryathanush%2FGanFET-Buck-Converter

https://github.com/suryathanush/GanFET-Buck-Converter

Please Review them and Give us your Feedback

Thank You

Surya Thanush