Other Parts Discussed in Thread: BQSTUDIO

Tool/software:

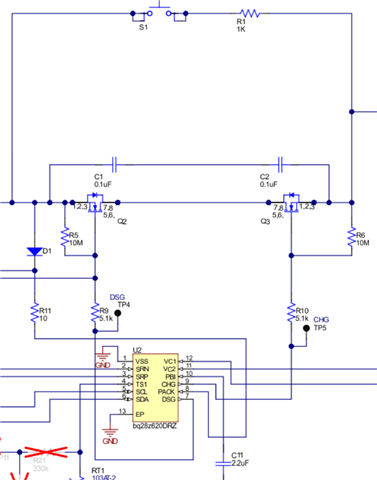

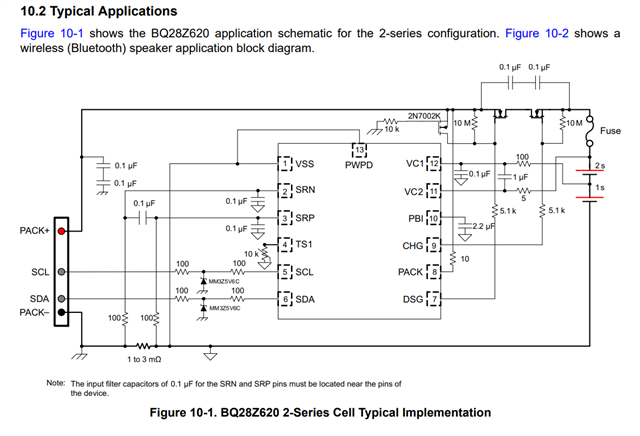

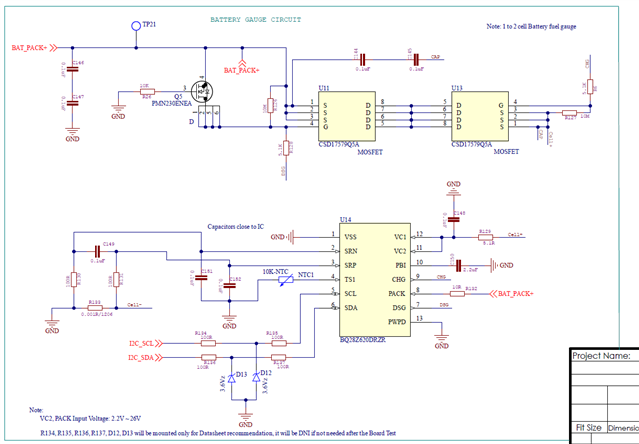

We are using BQ28Z620DRZR Gauge IC in our design for 3.6V single Li-Ion cell input.

1) When I am connecting single battery Li-Ion Cell 3.6V to the IC BQ28Z620DRZR VC1, VC2 pins, the CHG FET is ON, but DSG FET is OFF and voltage is not flowing to PACK input side, so in this case voltage is not flowing to loads such as like MCU, and other loads, etc.

But When I am connecting 3.6V to the PACK input side, both CHG FET & DSG FETs are ON. But in real-time not possible to connect like this, In this case how can we ON both CHG FET & DSG FETs through ICs VC1, VC2 single cell input voltage?

attached circuit for reference

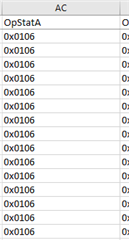

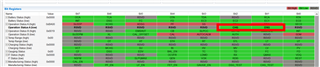

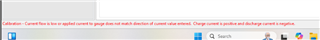

2) When we are using BQStudio for single battery cell calibration the INIT BIT is always ON. we need your input for how can we modify the INIT bit to LOW.

Any help is greatly appreciated.