Tool/software:

I listed some information below, along with a few questions, and was wondering if someone could help steer me in the right direction to help me understand and correct the issues I are seeing.

Also, who is the right applications engineer to discuss our concerns with?

We are having failures of your TPS7A3001DRBT when ran in high humidity environment (95% non-condensing) for two hours.

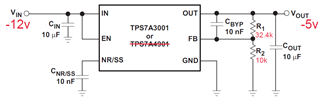

- Regulator configured for -5v output per table in specification sheet with supporting input/output 10uF capacitors and 10nF Cbyp and Cnr/ss capacitors.

- Failure is no output after soaked in humidity whereas the -5v goes to zero volts

- Upon Failure it is noticed that the NR/SS voltage measures ~-6VDC where in normal operation it measures -1.2VDC

- IC does not self-correct itself over time, however, will present a proper output again when power is cycled over time.

- Circuit schematic shown below

Additional Testing has been done of your TPS7A30 evaluation fixture which holds the TPS7A3001DGNT

- Different package configuration

- Regulator on fixture is also configured for -5v output

- Does not present failures at high humidity (running much longer test over weekend)