Other Parts Discussed in Thread: LM5122

Tool/software:

Hi TI Team,

I am currently working on a boost converter design using the LM51231-Q1 with the following specifications:

-

Input Voltage: 12V

-

Output Voltage: 36V

-

Output Current: 12A

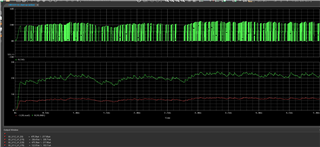

I found the TI Excel calculator for this design and have been following it, but I'm a bit confused about the loop compensation circuit and the bode plot. Specifically, the phase margin seems to be quite high, and I’m unsure if this is correct for the design.

Could someone help me understand if this specification is suitable for the LM51231-Q1, and whether a high phase margin is expected? I've attached the Excel sheet I’ve been working with for reference.

Any insights or suggestions would be greatly appreciated!

Thanks and Regards

Vinod J

0777.LM5123_Excel_Quickstart_Calculator_for_Boost_Controller_Design.xlsx