Tool/software:

Hi dear,

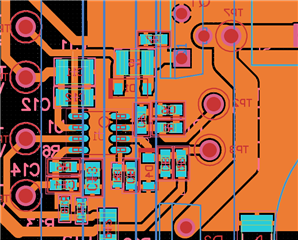

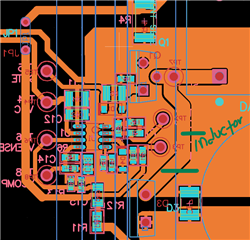

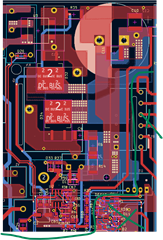

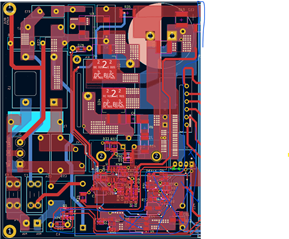

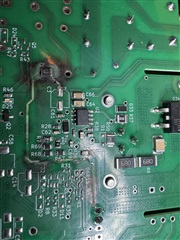

I am design a PFC boost converter based on the example TI has given. However, Upon powering up the PFC boost converter, it blow up. Attached is the schematic, PCB layout (exclude the blue zone, they are not part of the testing- no components are connected), and the blown up traces.

The nominal spacing is 2.5-3mm. However, the spacing between the ground plane and the PFC controller components is 0.25mm.Kindly review the schematic and check if i have missed out something that May have damaged the board.

The 12V, GND of the PFC controller is supplied with PSU.

The feedback trace to pin 6 and the 12V to VCC seems to have been damaged once the circuit was energised .

Boost Converter UCC28180 sch.pdf

Kind regards,

Bright