Other Parts Discussed in Thread: LM5121

Tool/software:

Hi,

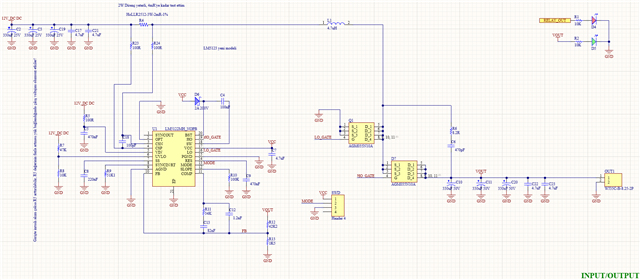

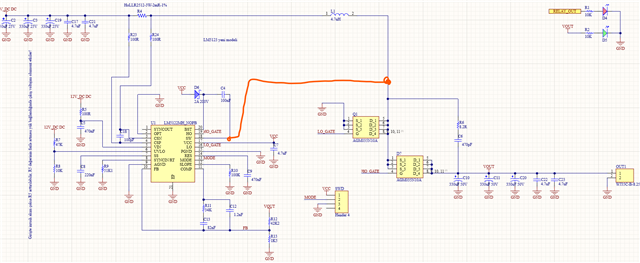

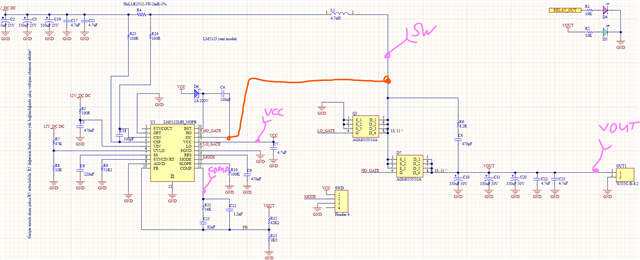

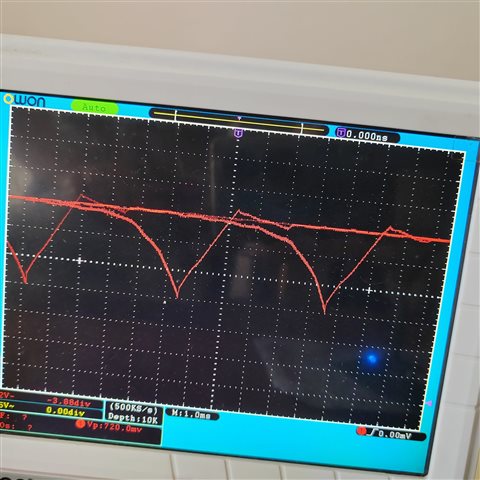

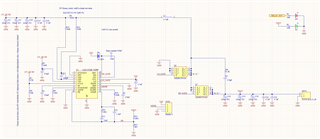

The output of my LM5122-based boost converter is stable at approximately 38 V when the only load is a power LED. However, as soon as I connect a DC motor, the output voltage ramps up and then collapses every 3–5 seconds, repeating this cycle indefinitely.

The bench power supply feeding the converter can deliver up to 10 A, which exceeds the motor’s inrush and running current.

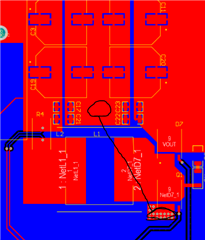

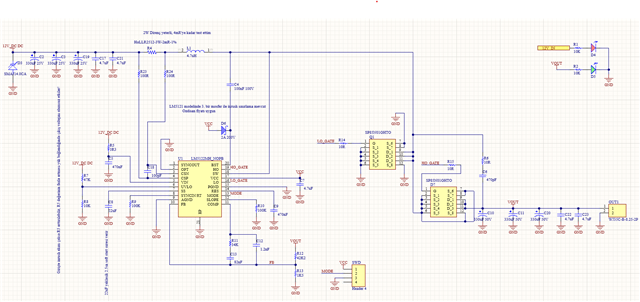

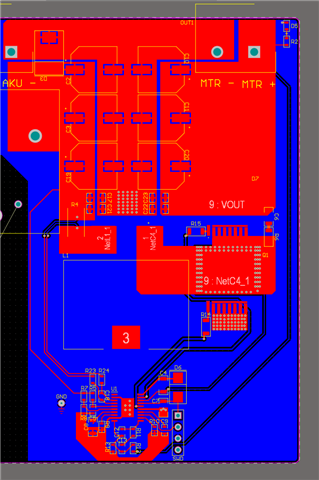

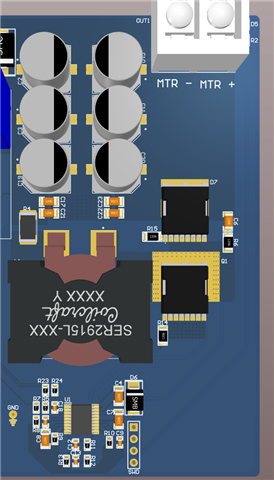

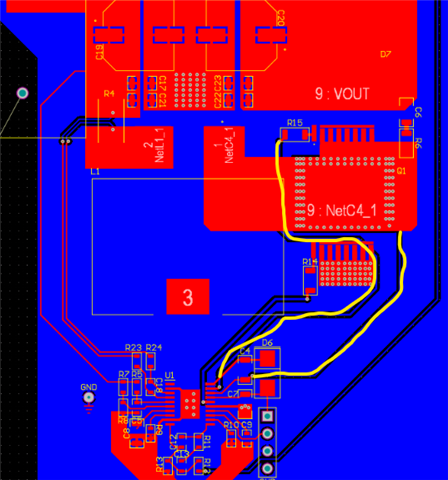

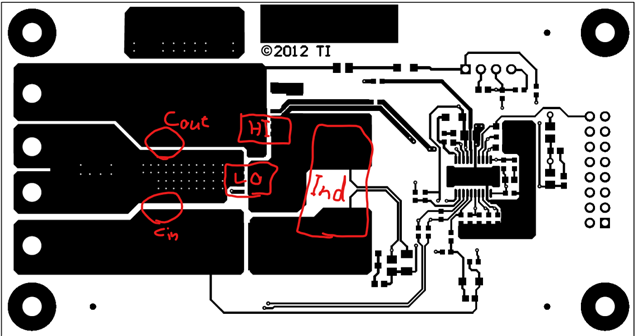

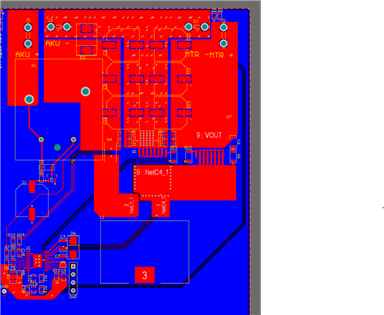

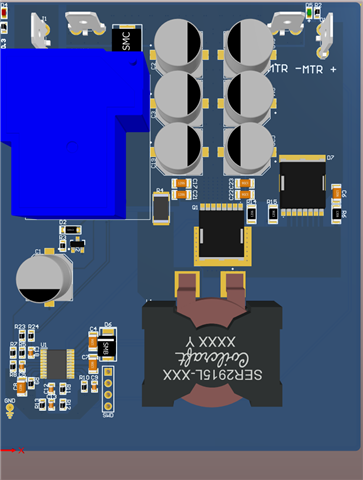

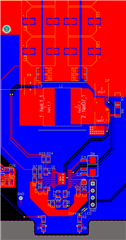

The schematic and PCB layout (attached) were copied from TI’s evaluation board, and I followed the layout guidelines as closely as possible.

What might be causing this periodic rise-and-fall behaviour under motor load, and how can I stabilise the output? Any suggestions for measurements or component changes would be appreciated.

Schmatic Image: https://ibb.co/ycnYxnRS