Tool/software:

Hello Team,

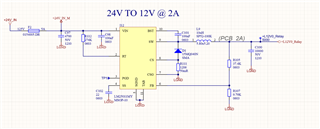

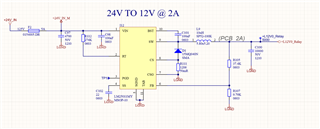

We are using the IC LM25011MY in one of our PCBs.

The input voltage is +24V and the designed output is 12V.

The load is some relays and the maximum load current is just below 1A.

The part number of the inductor is SP52-100K and that of diode is 15MQ040N.

The saturation current of the inductor is close to the load current

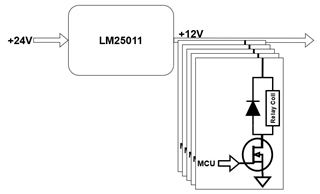

All relays are controlled by an MCU.

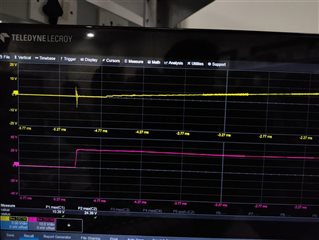

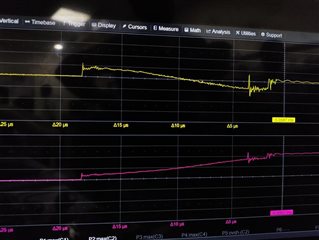

This DC DC got damaged when the MCU is reset.

Now the output is shorted to GND (checked across the diode).

The input is not shorted to GND.

Also, no short between input and output.

We see no reason to damage the DC DC when MCU is reset.

Can you please review the schematic?. And please let us know if there are any other reasons to damage teh IC.