Other Parts Discussed in Thread: BQSTUDIO

Tool/software:

Hi TI Team.

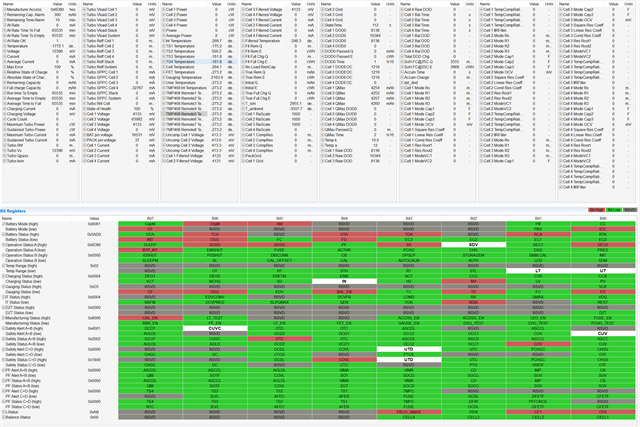

We have a battery pack that uses the BQ41Z50 that we have successfully run a learning cycle on and built a golden image from FW version 0.01 build 12.

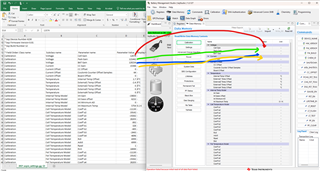

We would like to now create a new golden image that uses the latest V0.01 build 12 FW released April 25th without having to re-run the learning cycle and redo all the settings.

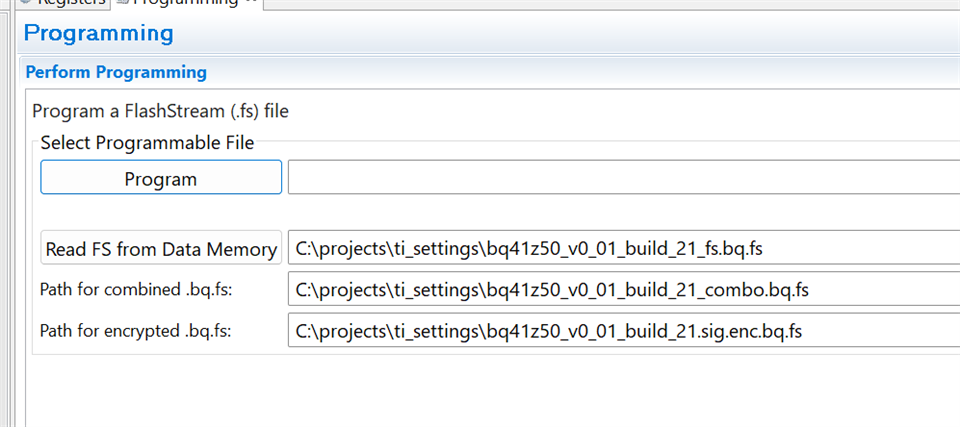

I tried simply adding the new firmware to the encrypted path assuming BQ Studio would create a combined image with the existing packs FS and add it to the new firmware image.

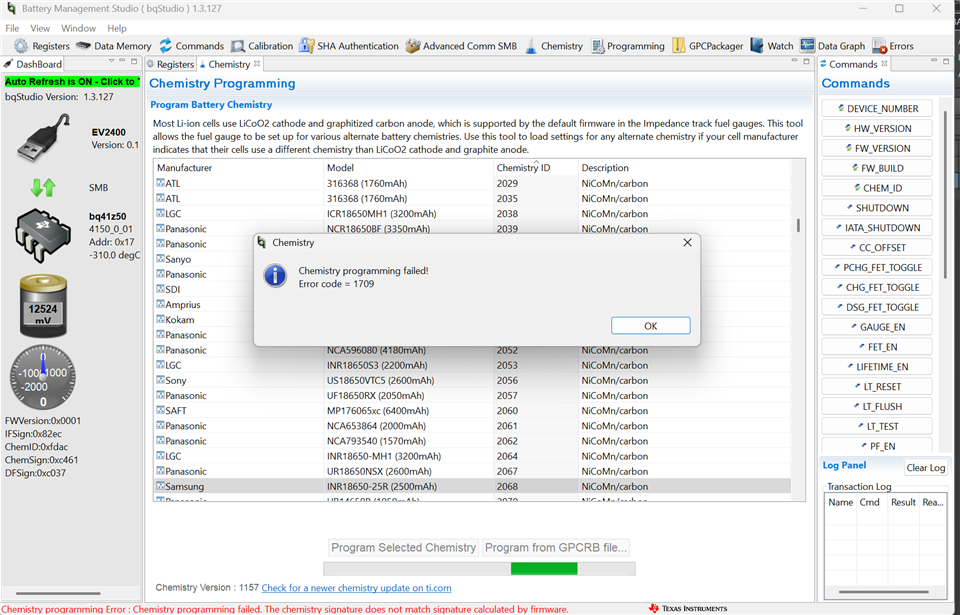

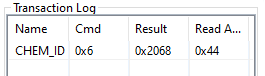

But when I program the new combined image, the Chem ID is changed, settings etc, so it looks like we are losing all of our data.

Is there a method to upgrade the Firmware to the latest without losing all our existing work?

Thank you.