Tool/software:

Dear TI,

I have some question on LMZ13608TZ.

Me and my team used this DCDC in many occasion with the same scheme and on the same board without problem but recently it seems unstable.

We use it to create a 5V output, that power up a CM4, from a 24 V input. Randomly (sometimes after a few hour, sometimes after days) the Vout goes up, over the 5V, and we see the pin 9 burned.

The PCB is the same as the old one that worked without problem, it's a different lot but it seems that the problem it's not in the different production.

Do you have any idea I can work with to resolve the issue?

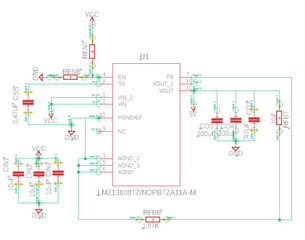

Here the schematic we are using:

Thank you for your disponibility,

Chiara