Other Parts Discussed in Thread: CSD18543Q3A

Tool/software:

Hi

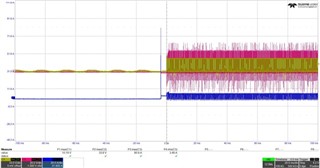

The inrush current comes out too high when starting up.

Is there any way to improve it?

The schematic cannot be disclosed for security reasons.

Can you tell me how I can deliver it personally?

Input:15V

Output:24V 3.5A

*Waveform

CH1 gate

CH2 Drain Voltage

CH3 Drain Current

Thanks