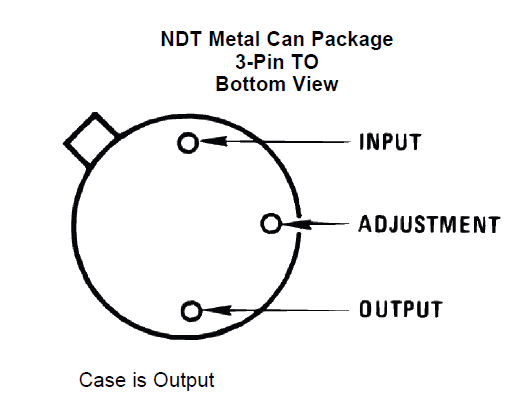

Other Parts Discussed in Thread: LM317

Tool/software:

Hello,

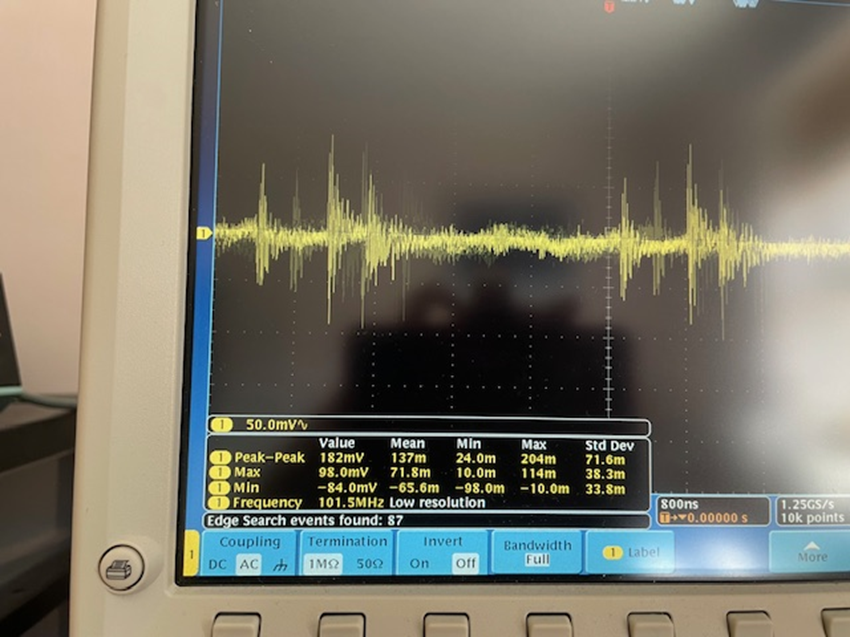

I am using the lm117 to generate a 2V rail, however, its output contains a lot of a.c. noise as shown below:

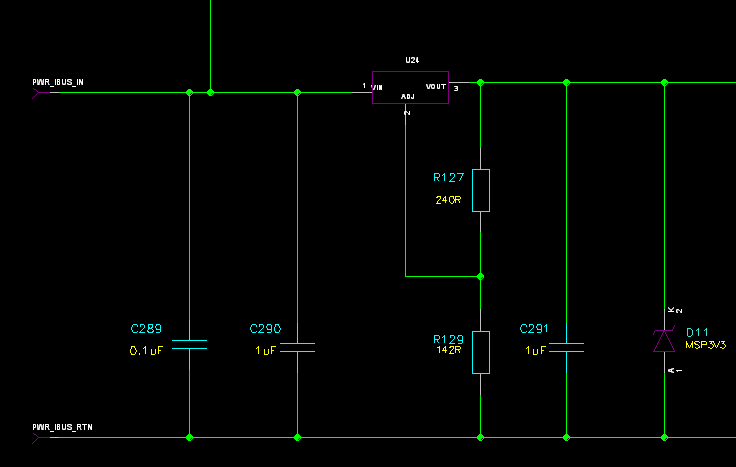

schematic is

I have added 220uF caps to both the input and output as well as a 10uF bypass across the ADJ pin, but the output is very noisy as shown above: the repercussion is that decoupling capacitors around the load are getting hot because the latter's ESR is being affected by the a.c. ripple riding on the 2V d.c. rail.

Is the above noise magnitude expected and how can I reduce it?

Thank you