Tool/software:

Hi,

I have designed a psfb dcdc converter 800V in, 120Vout, 600W. I've calculated the need for 40uH shim inductor. Transformer magnetizing inductance is about 6mH and leakage is about 11uH.

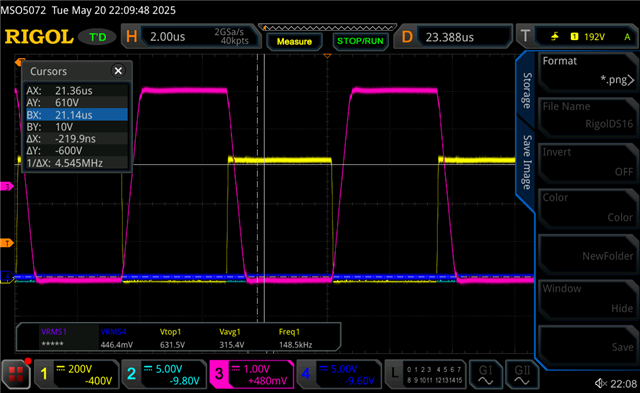

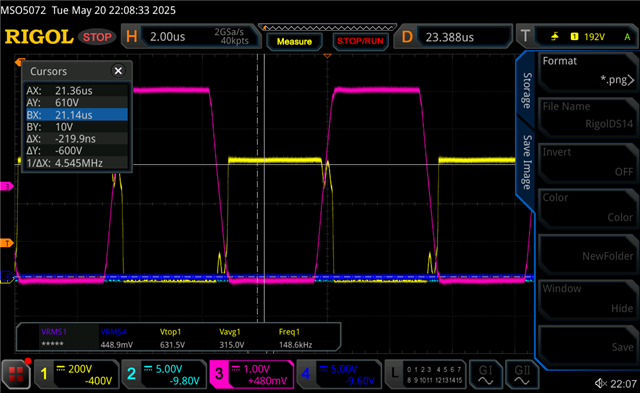

All works fine except the shim gets very hot. It seems I get very high voltage over the shim and saturate the core, which I didn't expect. To avoid this I need a physically very large inductor which is impractical.

Is this reasonable?