Other Parts Discussed in Thread: INA326,

Tool/software:

Hi TI Team,

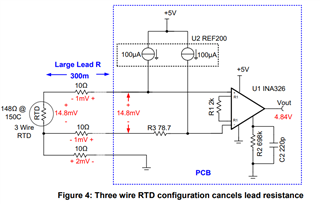

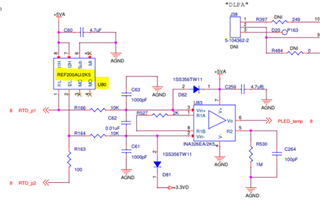

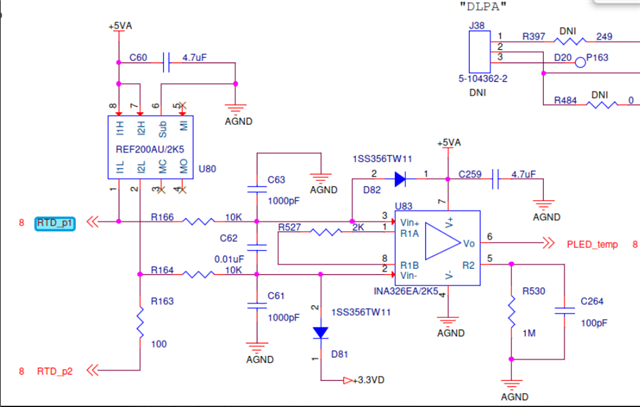

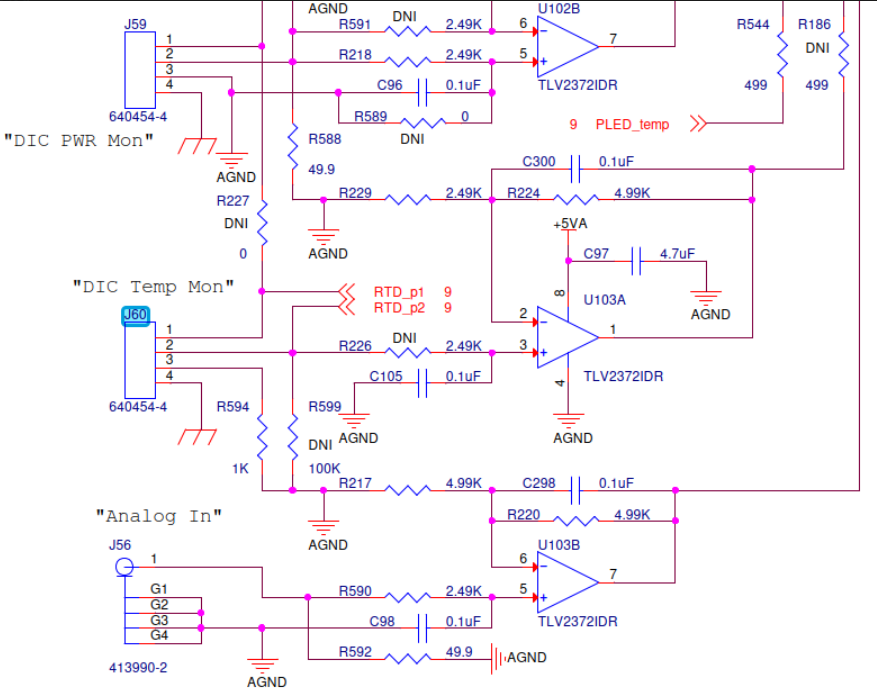

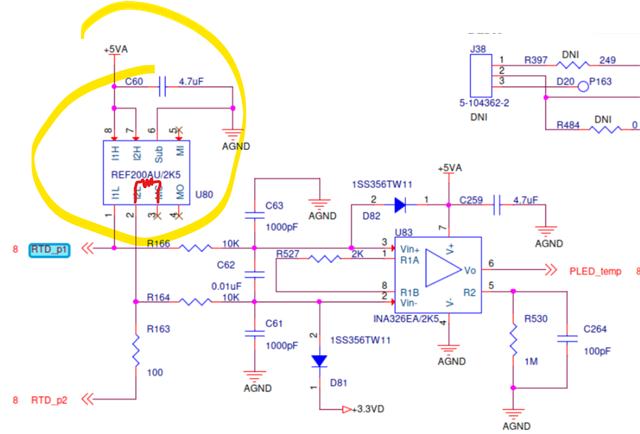

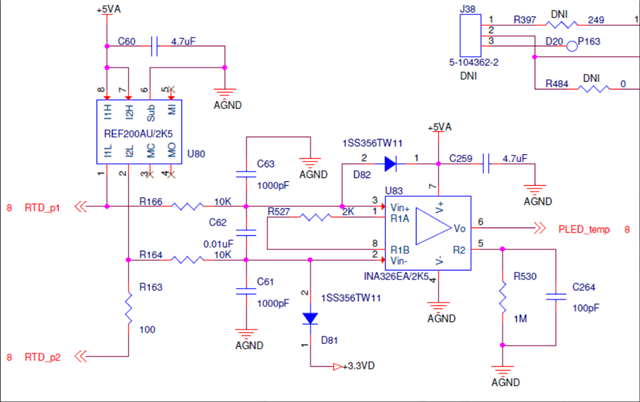

Our end customer is using a 3-wire RTD configuration with your REF200AU/2K5. They have a question regarding the impact of lead wire resistance.

In their setup, they are measuring approximately 0.9 ohms between the compensation lead and one of the RTD signal leads (effectively between what would be Pin 2 and Pin 3 in a typical 3-wire setup connected to an ADC or signal conditioner).

Per their understanding, this 0.9 ohm difference might cause the "noise" cancellation to be less accurate, potentially resulting in actual temperature readings that are lower or higher than the nominal value.

Could you please advise on the following:

- For the REF200AU/2K5, what is the acceptable tolerance or matching requirement for the lead resistances in a 3-wire RTD configuration to ensure accurate temperature measurement?

- Specifically, would a 0.9 ohm mismatch, as described, significantly impact the accuracy of the temperature reading when using the REF200AU/2K5?

- Are there any recommended calibration steps or compensation techniques within the REF200AU/2K5's features or in the accompanying circuitry that can mitigate the effects of such a resistance imbalance?

- Could this level of resistance imbalance cause any other issues with the device or the measurement system?

The customer's initial question was: "In the ideal case, pin 2 and 3 are shorted and near 0 Ohm but our test team's measurement, there is a 0.9 Ohm. Could you check if there is 0.9 Ohm across pin 2 and 3, will it cause any issue?"

Any guidance or documentation you can provide on this would be greatly appreciated.

Thanks