Other Parts Discussed in Thread: BQ25856-Q1, CSD19532Q5B

Tool/software:

Hello,

I would like some help reviewing a topology that I intend to use utilizing BQ25756 chargers.

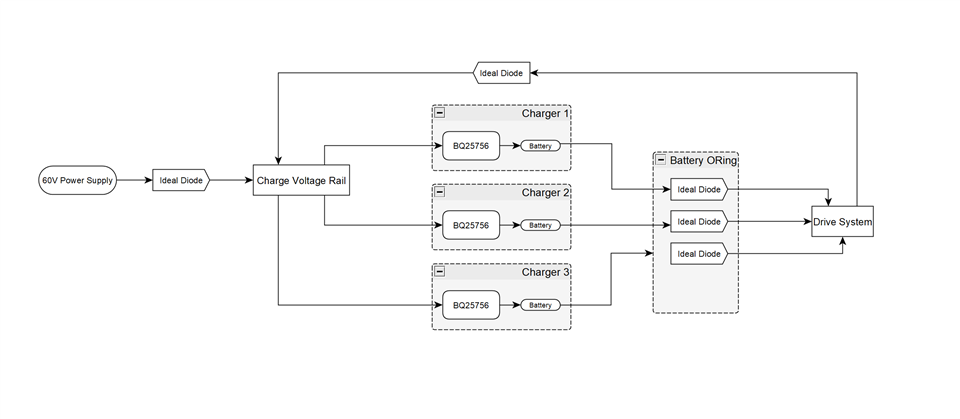

Below I have attached a diagram of what I want to do:

I have 3 batteries that require charging, and each of them are in parallel to power a motor driver for a ground rover. There are three batteries to allow for easy battery swap out but we also need a way for autonomous charging.

There is a host processor on this system to control the BQ25756s through multiple I2C interfaces or a mux.

I have a list of functions that I intend for this charging system to perform:

Normal Battery Charging using external power supply

All three chargers should utilize a 60V supply and use that to charge their attached batteries and power the drive system as well keeping it alive.

The input current should be limited individually by the host processor to not exceed the rating of the power supply

Regenerative Charging

If the rover is going downhill a significant amount of energy is returned to the shared voltage bus, and I want to be able to utilize this increased voltage to charge the batteries.

The host processor can keep measuring the voltage of the shared bus and switch on the chargers as required.

Would this setup work?

Some additional info:

- Battery Voltage max: 55V

- Max charge current: 15A

- Max 60V input supply current: 25A

- Max total load: 60A

- Max regenerative current: 20A

Any help with uncovering any major issues with this topology is greatly appreciated.

Thanks,

K