Tool/software:

Hi!

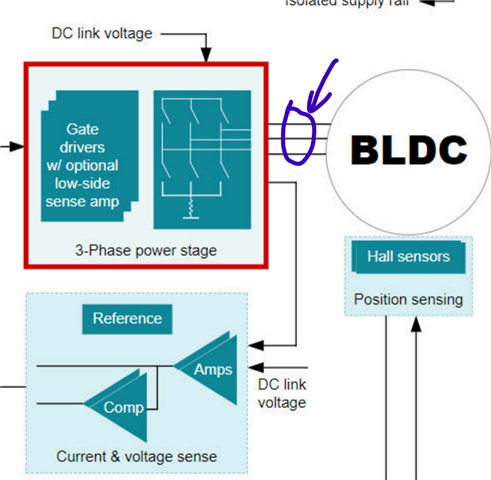

I need to protect short circuit on 3-phase motor 28V/60A avg max (120A SC, 100V absmax):

I know, that usually you protect on driver stage, but this protection is not working and I need to use this driver as is.

I cannot protect SC on input, because DC LINK burns driver in case of SC.

My calculated reaction time is 20uS, so TPS48xx looks fine.

The problem I see - I need to be conductive in PWM 0V-28V.

I will power 3xTPS48xx with external 28V DC, no problem. But will it be ok to pass PWM?

I want SC event will trigger cut-off other 2 phases, so I think to unite FLT open-drain signal on INP of each controller (INP pulled-up)

What do you think about it?

Do you have any reference design for my case?

Thanks!

Stas