Other Parts Discussed in Thread: LM66200

Tool/software:

Hello

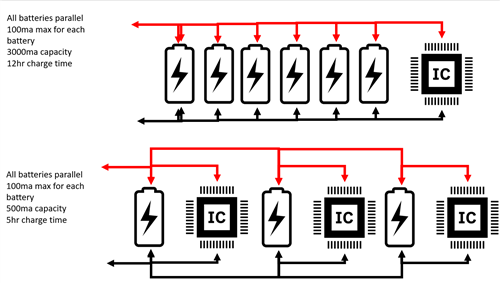

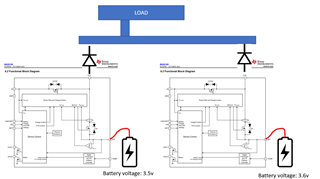

I am currently working on creating a custom battery pack for my application. I am using some specialized high temperature batteries in a 1S6P configuration. These batteries have a low charging maximum of 100ma, a 4.1v maximum, and a capacity of 500ma. I would like to use the BQ25185 circuit to charge these batteries. However, the combined capacity is about 3000mah. Each battery can charge at a maximum of 100ma, but I need to make sure that charging current is distributed evenly. My question: Is it possible to put multiple BQ25185 chargers in parallel each with its own cell for faster charging? See attached.