Other Parts Discussed in Thread: TPS25814, , BQ25731, TPD6S300, TPS26750, BQ25756, TPS25750

Tool/software:

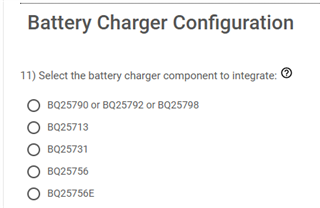

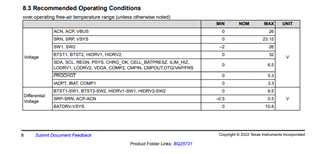

We have an application that will charge a USBC laptop at 65W while supporting a data channel. The data source would be an Ethernet to USB bridge. 24VDC is available to generate the charging voltages. The ideal solution would require no host MCU interaction to keep costs low. Low development effort and quick time to market are also critical. The TPS25751 appears to be a good fit, possibly the TPS25814 as well. Can the USB data from the Ethernet bridge be fed directly to the USB-C connector instead of the BC 1.2 from the TPS25751 or TPS25814. Or is there a better topology/more preferred approach? Thank you for your help.