Other Parts Discussed in Thread: BQSTUDIO, GPCCHEM, BQ34Z100

Tool/software:

Hi everyone,

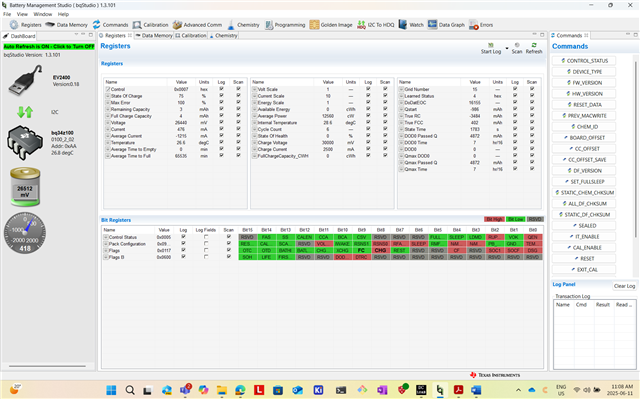

I am working on completing a successful learning cycle for a CANBAT LFP battery, which is 8s, 24V, 50Ah, and 128Wh. However, the gauge never learned, the update status is 04 before fully charged begins but never becomes 05 after fully charged and relaxed.

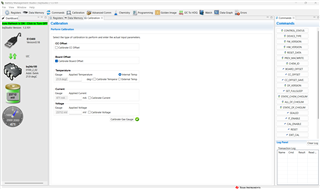

1. current offset issue:

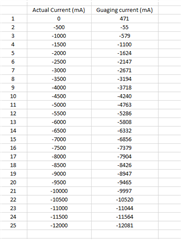

I suspect there is some BQstudio configuration issue because I always found there is a ~400mA current offset in the dashboard (attached below) without any charger and load connected. If I calibrate it to 100mA (I can't enter 0 mA, it will show an exceed range), the CC Gain will be a wrong number (~10). If I discharged it at 10A and calibrated it at -10A, the CC Gain and CC delta would be 0.486, which is quite accurate as the shunt resistor is 0.5mohm. so I keep CC gain and CC delta are 0.486 but there is ~400mA offset in the relaxation phase. I measured it actually ~0A by multimeter, Could anyone who has experience help me with that?

2. Chem-ID issue

I am also confused about the parameter configuration for the learning cycle. I am using 8s 24V, 50Ah, 128Wh, LFP battery. However, I don't know the accurate Chem-ID, I selected Lishen-LP44147132(50Ah)-0436-LFP, which has probably similar status. My colleague told me that exact ChemID is not very necessary for the learning cycle, a similar one should be good enough. I am not sure it is really unnecessary because I read it looks necessary in the TI document. I have contacted CANBAT support to see if they can provide chem-id or cell information.

3. SOC/Capacity monitoring issue in Bqstudio

The issue that I found is that when battery is actually 0% SOC, the BQSTUDIO shows 100% , when the battery is actually 100% SOC, the BQSTUDIO shows 0 SOC. After fully charged+2 hours relax, update never became 05, (it was 04). and the remaining capacity and full charge capacity are always strange number. I also attached the log file with the last fully charging and relax. You can see that SOC always keeps 100%.

4. Current scale question

Since I cannot enter 50 000 mAh in the register of Bqstudio, it is too large, so I used the current scale as 10, which means all the values related to the current need to divide by 10, like energy, capacity, and kinds of currents. However, for the current value I can directly read from the dashboard or registers, do I need to multiply 10? Since there is ~400mA in the dashboard without load and charged connected, if I multiply 10, which is 4A, so crazy.

Could anyone help me with those issues or questions and provide me with new ideas?

Thank you!

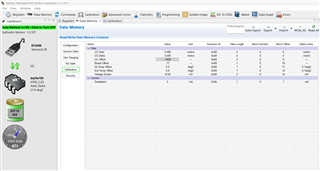

Here are the parameters I am setting:

Current scale: 10

Voltage scale:1

Energy scale:1

Number of series cells: 8 - I also set VOLTSEL =1

Design voltage: 3600mV

Design capacity: 5000mAh (scaled 10)

Design energy: 1280cWh (scaled 10)

Charge Termination Taper Current: 600mA (scaled 10, C/10, C=50Ah)

Cell Charge Voltage TX-TX-1: 3750mV: (Max charge voltage is 29.2V, but I measured the fully charged voltage will be 28.6V, so 28.6/8=3.75V)

Flash Update OK cell voltage: 2800mV: (22.5V at 0%SOC, so 22.5/8=2.8V)

Cell terminate voltage: 2800mV

Dsg current threshold:: 500mA (C/10, scaled 10)

Chg current threshold: 550mA (C/10, scaled 10, but should be lower than taper current, I know I have current offset issue, so I make this value higher that offset current)

Quit Current:250mA (should be lower that Chg/Dsg current threshold, C/20)

Cell V at Chg term:3750mV