Tool/software:

Hi,

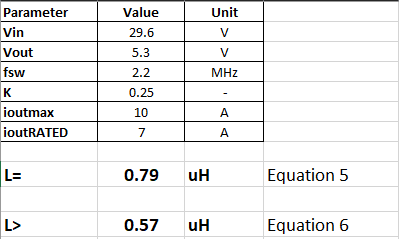

I am currently in the process of designing a buck converter using LM61495 to step down my 8s Li-ion pack voltage from 29.6V to 5.3V. The rated current is around 2A and the peak current is about 7A. I will assume a 10A of max current so we have some safety margin.

Then, I put my requirements into the TI Power Designer to get some initial ideas and I was recommended the following topology where a 560nH output inductor was used:

I then double-checked the datasheet of LM61495 and encountered equations 5 and 6 which are both used to determine the required output inductance.

Assuming Fsw = 2.21MHz, K = 0.3 and Imax = 10A, we get L ~= 660nH using Equation 5. If we use K =0.25, then it becomes 790nH.

However, my typical current draw is about 2A which means I would need a inductance of 2uH based on eqn 6. Given there is a such large discrepancy, which equation should i use to find my required output inductance?

Thank you so much in advance!