Other Parts Discussed in Thread: GAUGEPARCAL

Tool/software:

Hello,

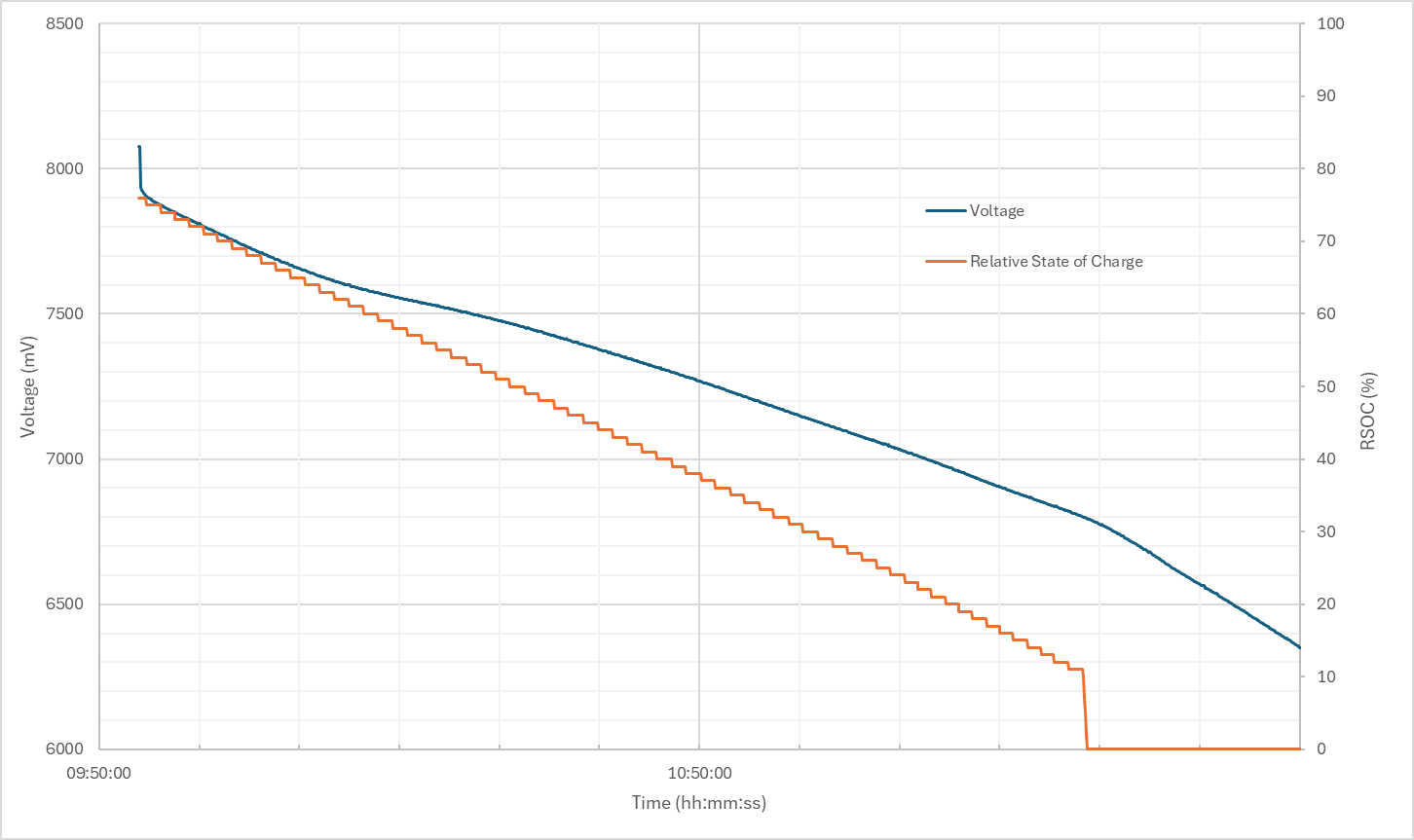

I have a 2S2P pack using the INR21700-50S (5000mAh), with the appropriate chemistry programmed from (https://dr-download.ti.com/secure/design-tools-simulation/design-tool/MD-lwtS0tg6h2/1061/ChemUpdate1061.zip) The pack is working well and all the values reported back seem good. However, a requirement has come up for the battery to report 0% over SMBUS when the cell has enough remaining capacity that corresponds to about 6.4V pack voltage. I am aware that this will mean a lot of the pack capacity won't be used.

I first assumed that it would be as simple as setting the FD or TD thresholds to 3200mV. However, looking at the Technical Reference Manual, I think changing FD (Fully discharged?) and TD (Terminate discharge?) would just turn off the discharge FET but not change the reported remaining capacity at this level.

Having looked around some more it looks like I may need to use https://www.ti.com/tool/GAUGEPARCAL and start with an "empty" (pack at 6.4v) pack, then do a full charge and discharge cycle while capturing the full csv from the battery management studio and then feeding it in to https://www.ti.com/powercalculator/docs/gpc/gpcUpload.tsp. Before I start all of that, is that the correct way to go about this, or is there a simple parameter I can change.

In summary:

1) Is it possible to rescale the 0% RSOC reading to an arbitrary point of my choosing

2) If yes, is there a way of doing it without using the GAUGEPARCAL?

3) If no, is my method of getting the data as I wrote above the correct way to go about this?

Thanks,

Tom