Tool/software:

Hello all,

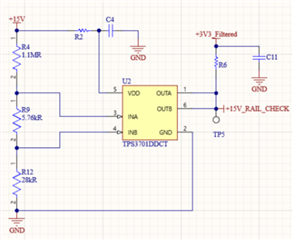

I’m currently using two TPS3701 (TPS3701DDCT) devices to monitor two separate voltage rails: +15V and -15V. These components, along with their supporting circuitry, are placed on a dedicated “Power Rail PCB,” which connects to a main control board.

Application Context:

The goal is to detect when either rail deviates beyond ±10% of its nominal value. If such a deviation occurs, the TPS3701 outputs a logic signal that is sent back to the control board.

This is the second revision of this design. In the earlier version, I used optocouplers instead of the TPS3701, with a 3.3V supply (for logic output pull-up) provided by the control board. However, that 3.3V line was quite noisy, resulting in unstable and unreliable logic signals from the optocouplers.

To improve reliability, I’ve switched to the TPS3701 in this revision.

My Question:

Given that the 3.3V supply from the control board might still be noisy, would it be viable (or advisable) to generate a cleaner 3.3V locally by using the +15V rail (already present on the Power Rail PCB) and stepping it down with a resistor divider for use as the VPU (pull-up voltage) for the TPS3701?

I’d appreciate any guidance or recommendations—especially regarding any risks or best practices when using a resistor divider for this purpose.

Best regards,

Kosta Kotsis