Other Parts Discussed in Thread: XTR300, XTR300EVM

Tool/software:

Hi,

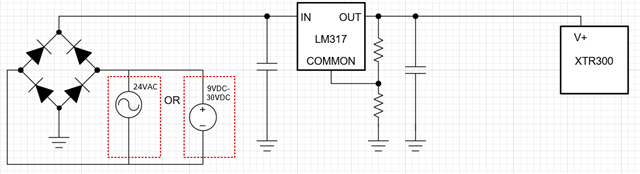

I would like to know if is possible to have a low ripple output to power XTR300, but the Voltage isn't regulated but should be the same Voltage Input afer Graetz Bridge but with very low noise ripple, so this request is because the customer could be power the board with 24 VAC or with 9..30 V DC, so my goal is to have the voltage in V+ XTR300 that depend from the power in.

I hope that my request is clear.

I've found the the LT3081 of Analog Devices could be this, but the simulation not regulated very good.

Thanks