Other Parts Discussed in Thread: TPS25750, BQ40Z50, TPS63802, TPS2560A, BQ25672

Tool/software:

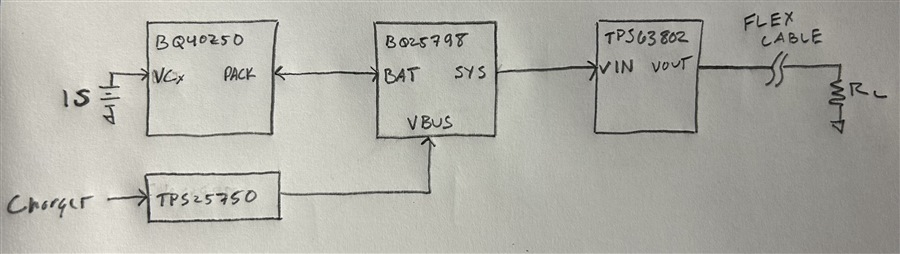

Hi there—our 1S design comprises TPS25750 + BQ25798 + BQ40Z50. The SYS output of the BQ25798 drives a 3.3-V buck/boost similar to TPS63802 (2-A continuous, 4-A peak switch current), which then drives a load by way of a flex cable. A simplified diagram of our power path is shown below:

We wish to implement short-circuit protection to prevent excessive temperature rise across the flex cable in case the downstream load fails short. The flex cable cannot withstand currents near the peak current limit of the TPS63802, and the maximum sustained short-circuit current must be limited to approximately 2 A.

At present, we use the over-current in discharge (OCD) function of the BQ40Z50 to protect everything downstream of SYS. This function is very convenient because it does not add to our standby power budget, and the delay is programmable.

However, this function can only protect everything downstream of SYS while the system operates from battery power. While the system operates from charger power, the BQ40Z50 is effectively bypassed and the peak switch current of the TPS63802 becomes the limiting factor.

We have considered adding a current-limited load switch such as TPS2560A after SYS, but the reaction time of these devices is too short (~3.5 us). The load downstream of the flex cable can demand 3–4 A of inrush for 1–2 ms, and there is too much risk that a fast-reacting load switch may interrupt prematurely. Our only other idea is a fuse, but its behavior is not well controlled.

We are seeking ideas on how to implement HW-redundant short-circuit protection that can cover both the battery-powered and charger-powered cases. Can TI recommend any other solutions that we may not have considered? Thank you in advance—in case I can provide any additional information about our application, please let me know.