Other Parts Discussed in Thread: BQ25798, , EV2400

Tool/software:

I am developing a new instrument which includes the BQ25792 to manage the battery charging and USB power.

We have been working with the first prototype PCB's and had 3 with apparently failed BQ25792's.

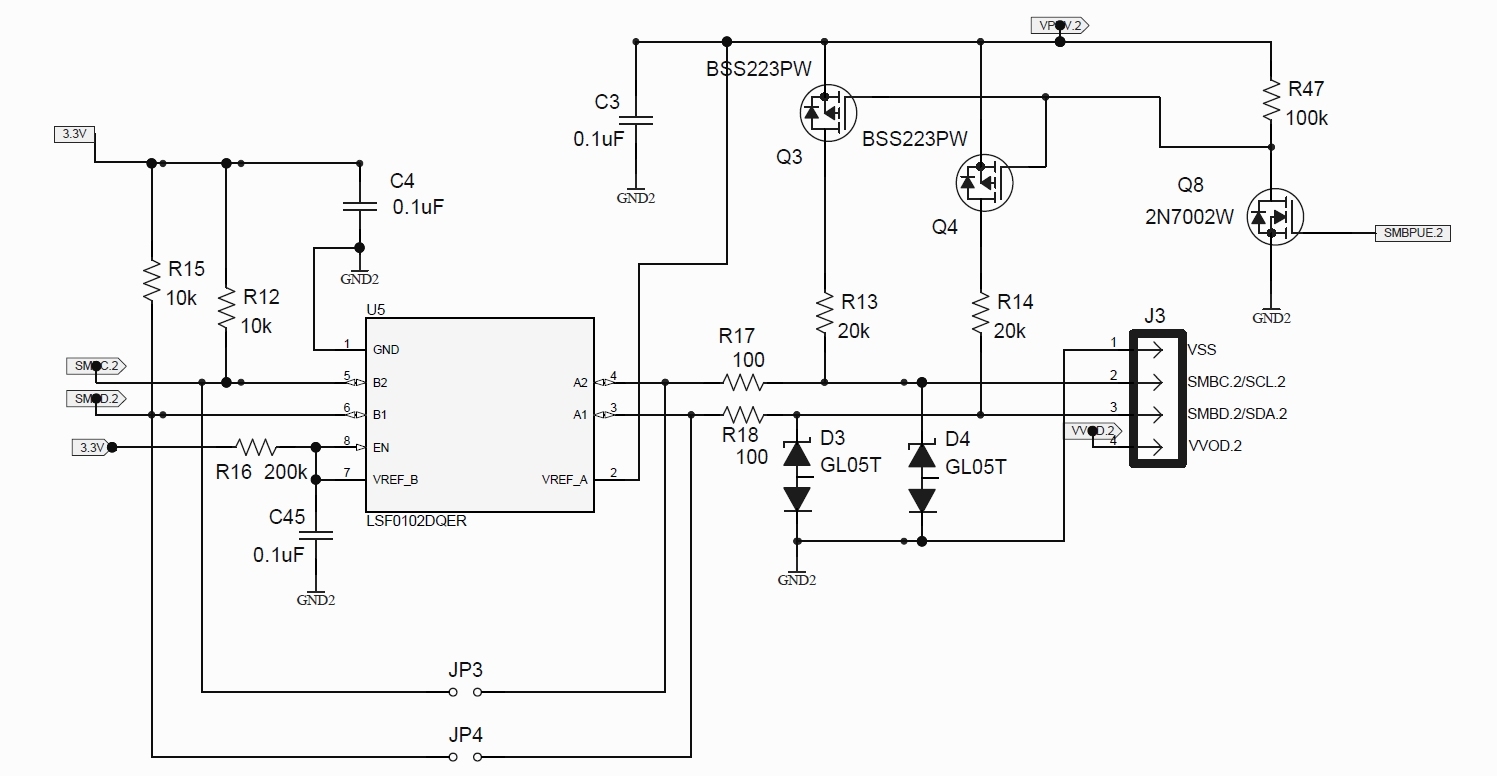

This is the charger part of the schematic:-

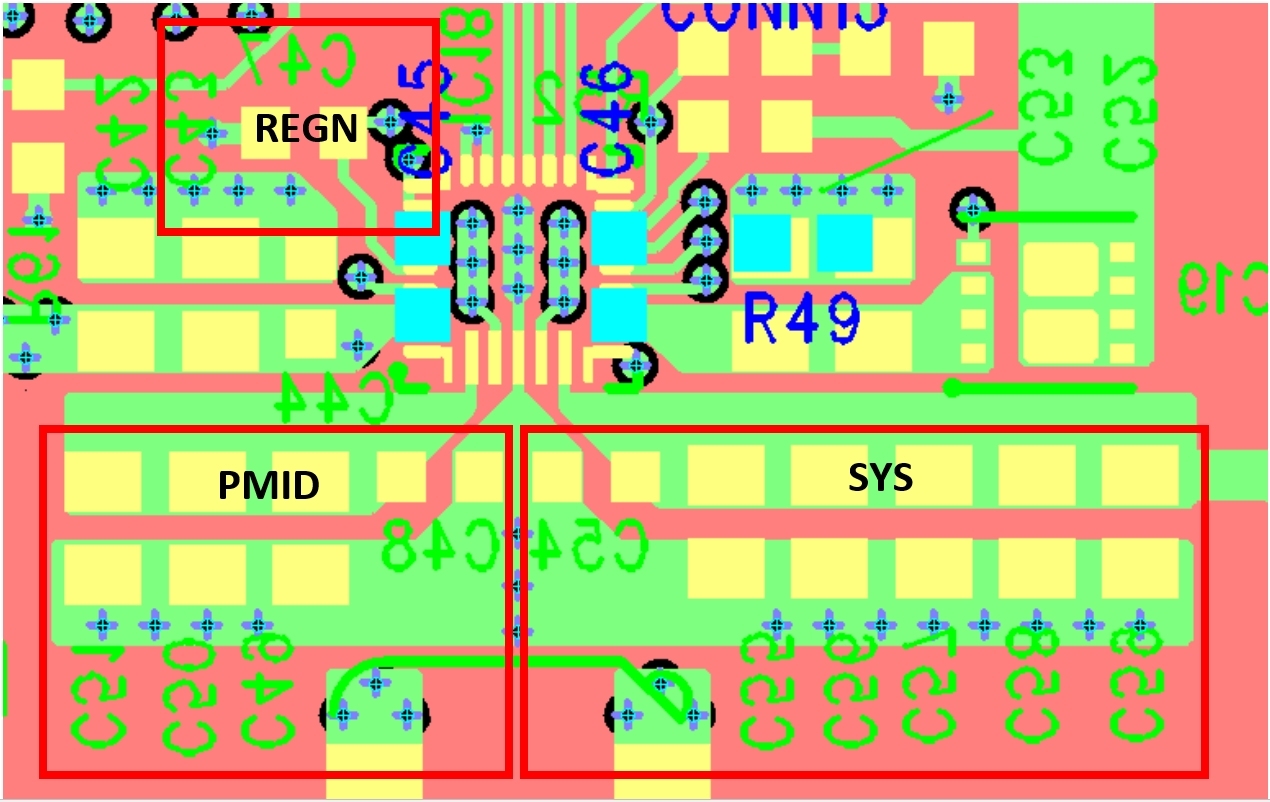

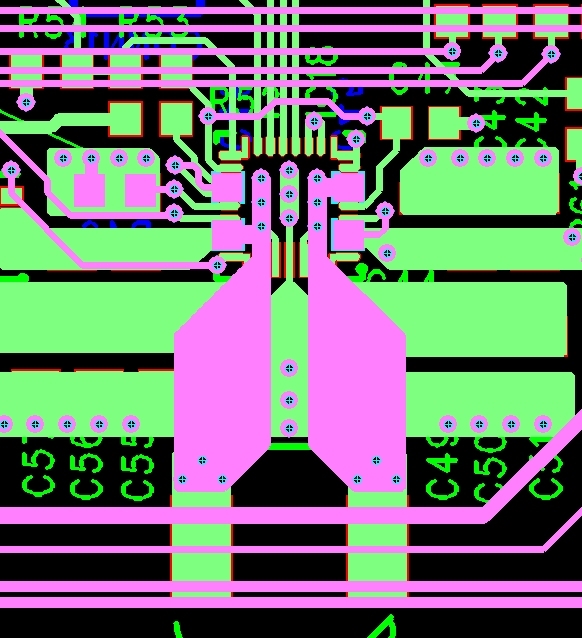

This is the charger layout:-

The VBUS comes from a 5V 2.5A USB charger. The battery is a 21700 2S1P 7.2V 4.9Ah.

We rely on the SYS output to power the rest of the circuit.

A button connected to SYS at BUTTON_ON turns Q5 on, then a PIC holds it on at POWER_ON until the system is turned off.

When we get this failure, the SYS output just stays at close to 0V with VBUS connected, the battery connected, or both.

We suspect it may be related to a register setting we are applying, but cannot pin it down to a particular one.

It may also only happen when a battery is connected. Running just on VBUS hasn't caused the failure as yet.

Registers we were setting are:-

CHARGER_CONTROL_1,0 - DISABLE WATCHDOG TIMER

CHARGER_CONTROL_0,176 - ENABLE ICO

CHARGER_CONTROL_5,183 - ENABLE SHIP FET; ENABLE IBAT DISCHARGE CURRENT SENSING FOR ADC; ENABLE BATTERY DISCHARGING CURRENT OCP

PRECHARGE_CONTROL, 198 - 240mA

MINIMAL_SYSTEM_VOLTAGE, 18 - 7V

CHARGE_VOLTAGE_LIMIT, 840 - 8.4V

CHARGE_CURRENT_LIMIT, 50 - 500mA

INPUT_CURRENT_LIMIT, 300 - 3A

ADC_CONTROL, 0x8c - ENABLE ADC; 15BIT; START AV USING NEW ADC CONVERSION

I have since read that BQ25798 may be a better option for us, as in some applications a battery won't be fitted.

BQ25798 is more suitable if a battery might not be fitted in some applications? Is that correct?

Are there any differences between BQ25792 and BQ25798 we need to consider if we change?

It appears to be a PIN2PIN equivalent physically, but are there any register differences or other circuit differences we will need to consider?

Thanks in advance for any help you can provide.

Best Regards,

Julian Kent