Other Parts Discussed in Thread: BQSTUDIO, BQ27Z746, GPCCHEM

Tool/software:

Hello,

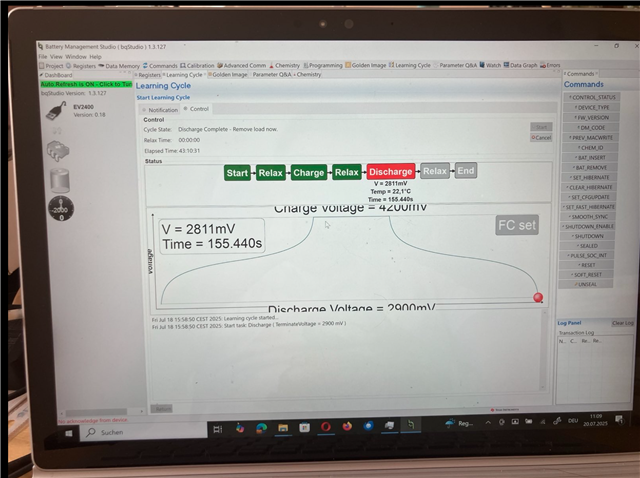

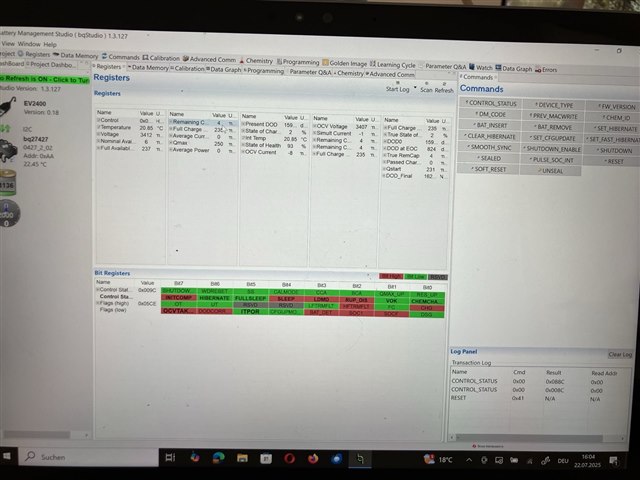

we have a design, that makes use of a BQ27427 with a lithium-ion polymer battery from Renata (ICP521630PJ-05), connected to a microcontroller (nRF53) that runs Zephyr-OS (and makes use of their fuel gauge driver).

When I fully charge the battery and then slowly discharge the battery (over the course of a day), the state of charge drops slowly until 5%. When the microcontroller detects the SOC of 5%, it disconnects the battery and the gauge using a PMIC (PCA9420BS). The gauge is not put into SHUTDOWN mode.

When starting to charge the battery, the PMIC connects to the gauge and battery again. The first SOC, that we get from the gauge is 6%, which seems to be very reasonable. But the next values seem to be way to high, after a few seconds, the next reported SOC is already 59%.

Indeed, stop charging, the reported SOC drops slowly and a last reported SOC is then 43% and the device brown outs.

The Charging Voltage of the battery is 4.2V, so we picked 1202 as Chem ID.

What can we do, to adapt the gauge SOC estimation better to our battery?

best regards

Torsten