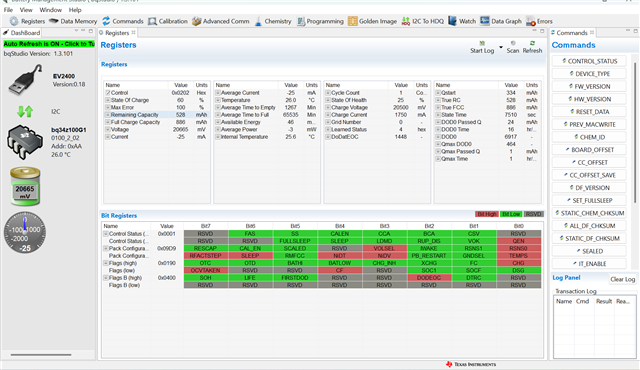

Other Parts Discussed in Thread: BQ34Z100, EV2400, BQSTUDIO

Tool/software:

Hi

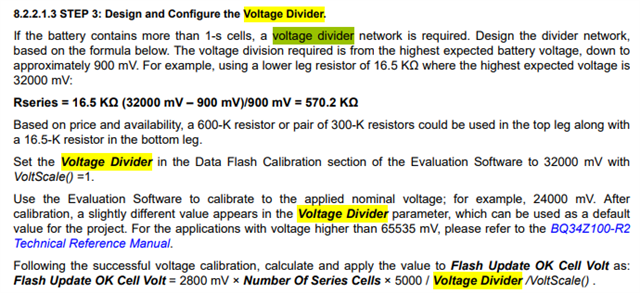

We are planning to use 3S1P dump pack in our product.

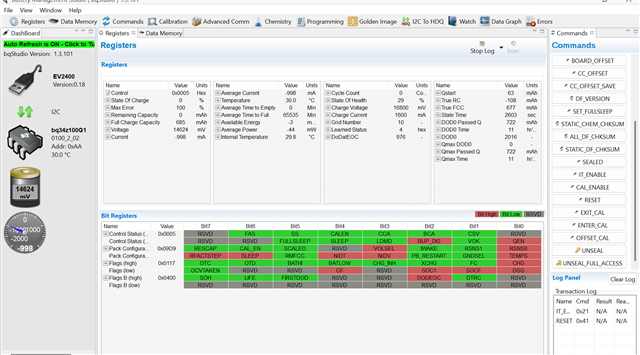

We need to display the SOC accurately, so for thar shall we use BQ34Z100-R2.

By Using SMbus communication could it can be done with this IC.

Regards

MAX