Tool/software:

Hello,

We used the part in our design as a regulator from +24V input to +5V. When powered up for the first time with +24V applied and minimal load (around 50mA), it regulates to the intended voltage by around 20 seconds and then the input current rises, it stops to regulate the output and heat up dramatically. After that the device is permanently damaged and it does not return to the initial behavior if power off and on. We found out that if the input voltage is smaller than 15V, the catastrophic failure does not happen, at least in the observed time.

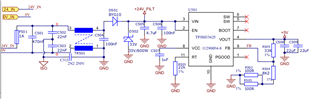

Please find the schematics below. We checked against the datasheet and could not find any discrepancies. The fact that it does work as intended for a small amount of time seems to be an indication that the general connections are ok. Also, we could not figure out what could cause such a catastrophic failure.

We also experimented increasing the input capacitance with a low ESR capacitor, to no effect. In one test, we applied the input directly to +24_FILT node, with the same outcome.

Do you have any suggestions of how to proceed? What could cause such catastrophic failure in this part? Is there any know history of counterfeits for this part that could explain this issue?

Thanks in advance