Other Parts Discussed in Thread: TPSM843B22, LM25145, TPS56221, LM5145, LM5145EVM-HD-20A

Tool/software:

Hello,

We are currently running tests on a TPSM843B22EVM Step-Down Module Evaluation Module, to determine if the TPSM843B22 power module is applicable for our application.

Vin is supplied by a 15V, 600W DC power supply.

Vout is driving a diode array (to simulate a high-power laser emitter) and is set to 5V.

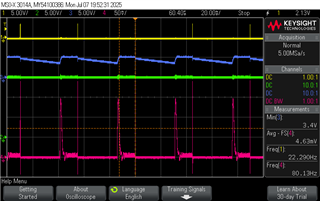

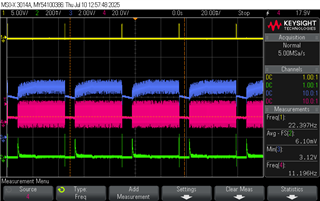

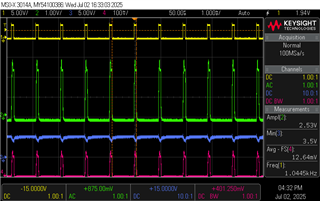

We are attempting to send high current (100-150A), 5V pulses to the load through a laser driver. We’re controlling the current, width and frequency of the pulses. From my testing, the power module seems to become unstable around 100A, 100us, 1kHz (see oscilloscope shots below).

FSEL=2200Khz MSEL=HCL:2pF:2ms

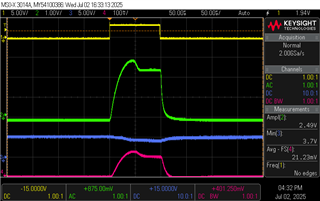

- Trigger signal (controls the frequency/pulse width)

- Current monitor at the laser driver (scale: 40A/V)

- Vout of the TPSM843B22 Power Module

- Current Probe on the input of the load (scale: 1mV/A)

The power module appears to be going in to over current protection mode after running at these settings for a couple minutes. Is the behavior seen below expected in over current mode? Vout is pulled down to ~1V and becomes unstable, the frequency must be decreased to about 400Hz before operation is restored.

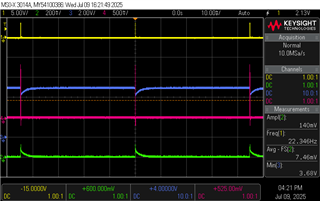

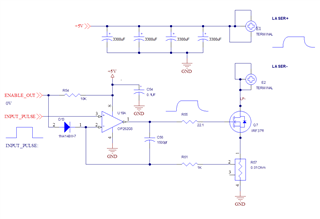

Here is a simplified schematic of the laser driver’s current source for reference. Most of the current to the laser comes from the capacitor bank, the power module supplies supplemental current during the pulse and charges the capacitors between pulses.

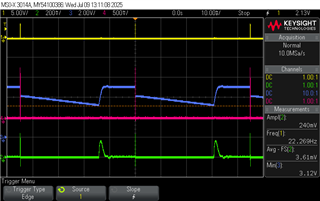

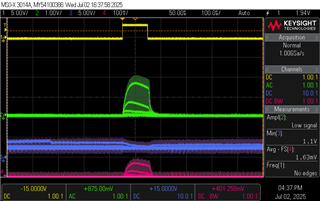

During the operating conditions described above, the current through the Power module spikes to 20A every time a pulse occurs.

I attempted to increase the output current to 120A and damaged the power module (It only allows small amounts of current to pass, otherwise Vout gets pulled down to 2V).

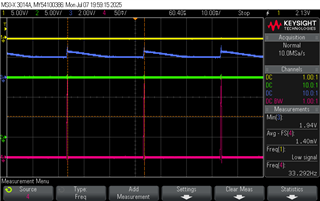

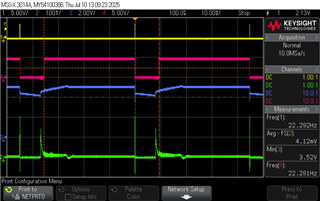

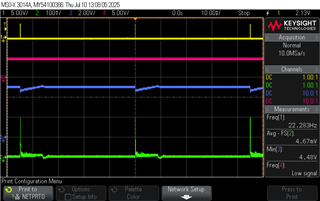

In the scope shot below, input power (red) comes from the 5V rail of an ATX power supply (No Power Module), otherwise the operating parameters are the same. This is to demonstrate the current waveform through the power module.

- Trigger signal (controls the frequency/pulse width)

- Current monitor at the laser driver (scale: 40A/V)

- Voltage across the capacitors

- Current Probe on the input Power

Should we expect the power module to be stable if the current peak is below 20A at 15Vin/5Vout?

Vout of the power module drops from 5V to 3.7V. Is this voltage drop too large?

When powered, we have a capacitor bank of 13.2mF (four 3300uF capacitors in parallel) attached to Vout. Is this suitable for the power module’s operation?

I noticed no change in behavior when changing the FSEL and MSEL jumpers.

Can you please help us to understand if this power module is applicable for our use case? Are there any design considerations we can change to improve performance? Is there another DC-DC power converter that may be better suited for this application?

Thank you!