Other Parts Discussed in Thread: INA180, TPS92640, TPS92641

Tool/software:

Hi everyone,

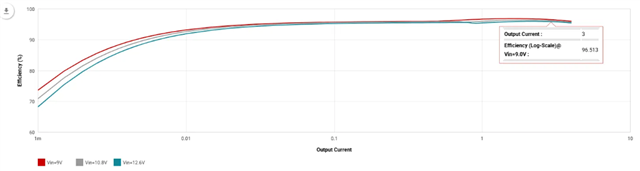

I want to use two TPS56637 fed from a 3-cell Li-ion pack for drive high power LED. One buck is set for ≈ 3 V, the other for ≈ 6 V (both up to 4 A). Each runs in FCCM to avoid skip-mode flicker. A 7 mΩ sense resistor plus an INA180 (gain 20) closes the loop on FB, so the parts behave as constant-current drivers. I chose it because WEBENCH® Power Designer shows me very good efficiencies at 96% over a wide current range. I want to be able to vary my current in several steps between min 100 mA and max 4A.

efficiency curve from WEBENCH® Power Designer

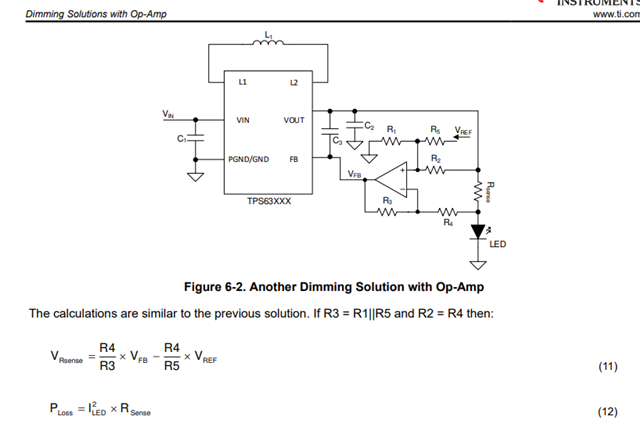

Dimming Solution with Op-Amp from TI Application Report (https://www.ti.com/lit/an/slva419d/slva419d.pdf?ts=1752345436091)

I still have three doubts:

- High-speed PWM on EN. With the fixed 2 ms soft-start, a 25 kHz EN signal never lets the inductor current reach its target. Is the right approach to keep EN high and do any fast PWM with a downstream series FET instead or do analog dimming ?

- Analog dimming through the INA is a good idea ?. I inject 0–1.2 V from a DAC onto FB (simple 10 kΩ divider) to cover roughly 50 mA → 4 A with no PWM. Any practical feedback on accuracy and noise at the low end

- Parts choice. If there’s a TI LED-oriented buck with synchronous FETs ≤ 20 mΩ, good stock, and similar efficiency but an even cleaner CV-to-CC path, I’d love to hear about it or other solution. It is important to stay with a very high efficiency > 95% if possible.

Thanks a lot!

Best,

Marius