Other Parts Discussed in Thread: TIDA-00443

Tool/software:

Subject: Clarification on CE Emission Compliance & Support for UCC28180-based 650W PFC Design

Dear TI Support Team-,

Dear Tom,

We are currently using the UCC28180 PFC controller in one of our designs with the following specifications:

-

PFC Output Power: 650W

- Input Voltage Range: 165Vac to 280Vac

-

Output Voltage: 396VDC

-

Switching Frequency: 70kHz

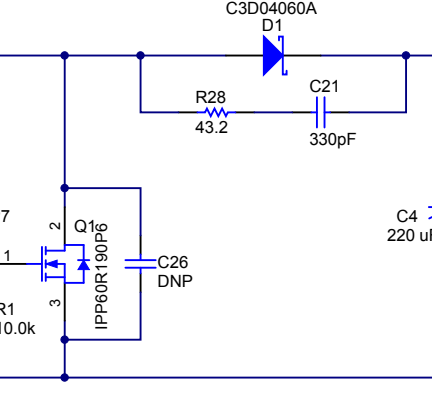

We are facing an issue during Conducted Emission (CE) testing as per EN 55014-1 Class B. The CE test results show peaks in both Quasi Peak and Average levels in the frequency range of 9 MHz to 16 MHz.

To analyze this, we referred to TI’s reference design TIDA-00443 (900W PFC design). In the CE results for TIDA-00443, we observe emissions peaking around 18 MHz to 30 MHz. However, the reference guide does not clearly mention whether the results pertain to Class A or Class B compliance. Could you please clarify this?

Additionally, please find attached our CE test results (PDF) for reference.

We would also like to know:

-

Does TI offer any reference design compliant with EN 55014-1 or EN 55032 Class B for power levels ≥500W, ideally around 650W?

-

Are there any updates or design guidelines for UCC28180 specifically addressing CE compliance?

-

Any recommendations for filtering or layout changes to reduce the 9–16 MHz conducted emissions?

We appreciate your support and look forward to your guidance.

Best regards,

BR Kadam