Other Parts Discussed in Thread: TIDA-050030, TPS92682-Q1

Tool/software:

Hello Expert

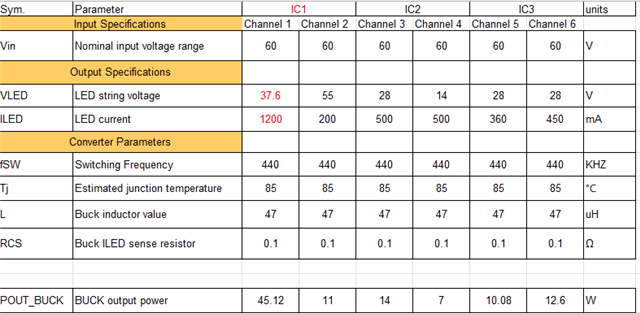

I have a Headlight quote project which we want to use 1*TPS92682 with 2 phase CV boost and 3* TPS92520 CC buck .

Related requirements as below shown:

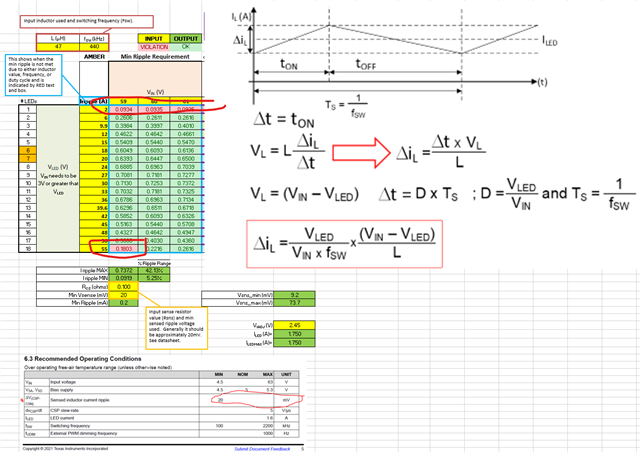

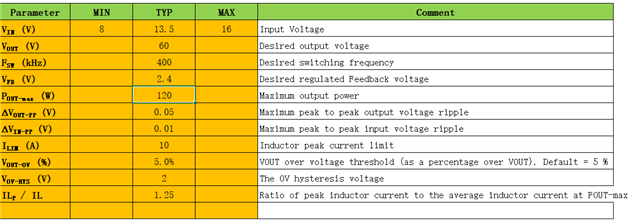

For TPS92682 2* phase CV boost:

For TPS92520 CC buck:

Input voltage: 60V

Output voltage range: 2-55V

Output current rang: 0.1-1.5A

1 channel need to support Max.45W 37.6V/1200mA

other 5 channel need to support Max. 30W。

totally allowed output power Max. 100W

I list the possible power dissipation distribution for your reference,

my question:

1) CV boost output 60V, CC up to 55V, is it OK or not?

2) CC chip IC1 one channel 45W, tot 56W, is it OK or not?

3) Do you have power dissipation calculation sheet without PROT contain TPS92682 and TPS92520 can share to me?

4) Is it possible to use TIDA-050030 120W Dual-Stage Matrix Compatible Automotive Headlight ECU Reference Design for quickly quote EBOM?

5) Do you have detail 2 phase CV boost step by step application calculation method for external E-parts share to me ?

6) which is max. allowed power dissipation for TPS92682 2phase CV and TPS92520?

other unclear information, let me know.

Thanks in advance!