Tool/software:

Hi,

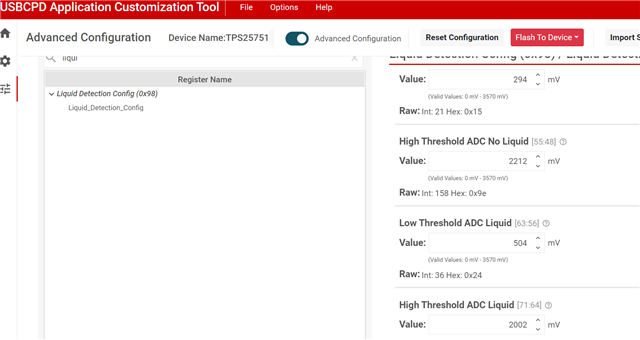

We are using TP 25751 USB PD controller and we have enabled the liquid detection with it through the USBC customization tool to generate the binary. We want to check the liquid detection with different configuration of the register 0x98 Liquid detection configuration register.

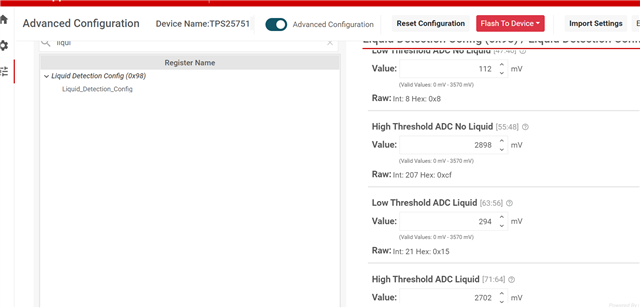

Can you help us to know the different values to write in the configuration register so we can increase the sensitivity for liquid detection like:

1. The controller can detect the moisture or liquid when the liquid amount or moisture content is high.

2. The controller can detect the lowest amount of moisture or liquid.

To test these scenarios what values would you suggest we can change in the configuration register? Please provide the reference and example values.

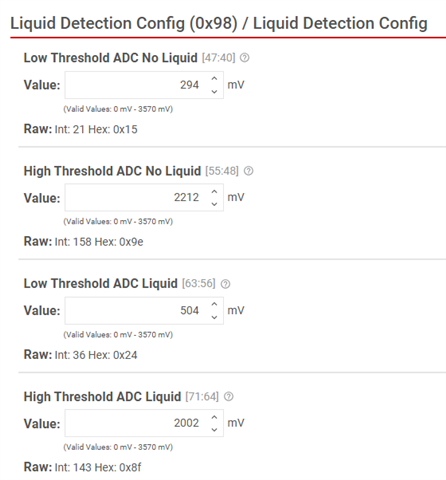

The by default values that we have read from the controller is:

001\0\001\0\002\021\158\36\143\170\6