Other Parts Discussed in Thread: TPS25751

Tool/software:

Hi teams,

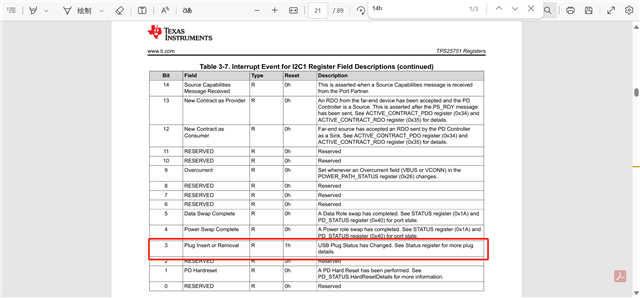

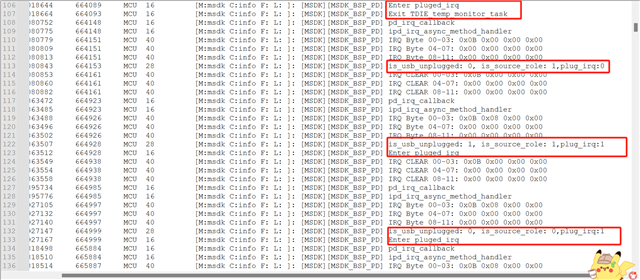

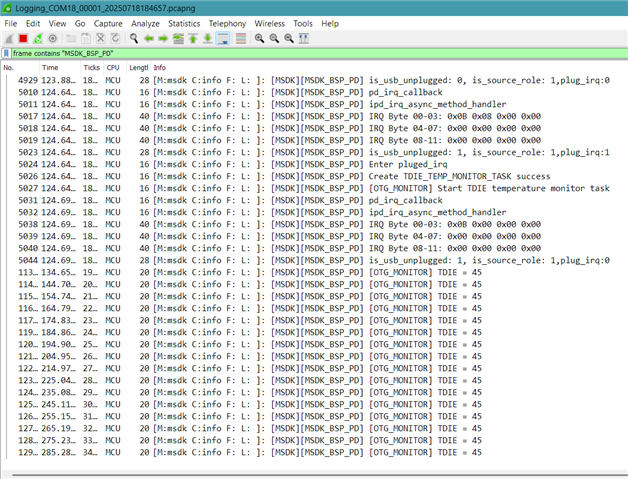

We encountered the following problem when reading the built-in NTC temperature of BQ25798: the hot air gun blows the charger IC, but the temperature remains the same

The steps we read are as follows:

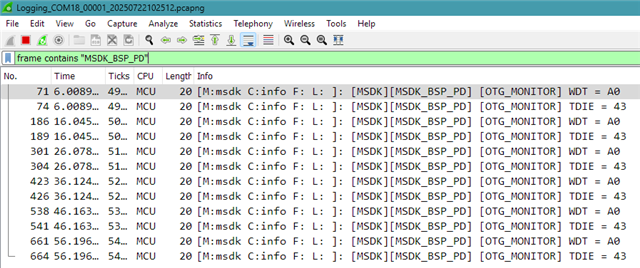

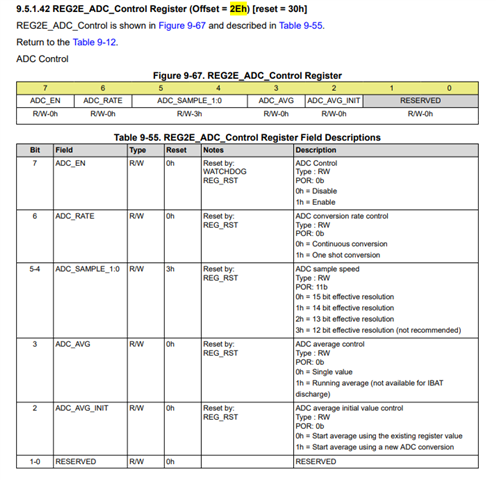

① Enable ADC, write 0xC4 to REG2E_ADC_Control Register (Offset=2Eh)

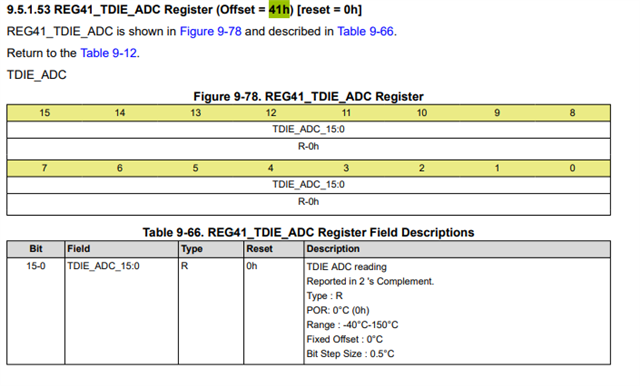

② Read REG41_TDIE-ADC Register (Offset=41h) register

③ Cycle every 10 seconds

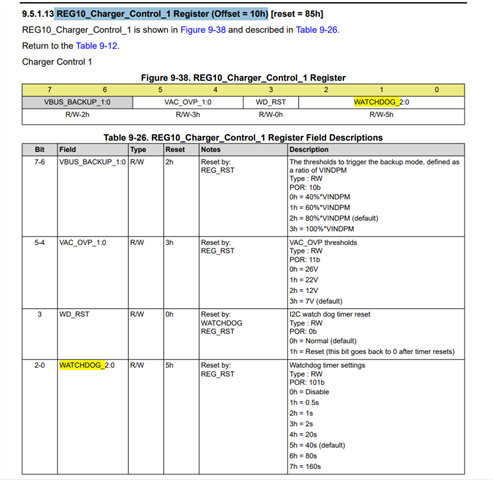

But we found that when we used a hot air gun to blow the charger IC, the data read back remained unchanged at 45. Due to Bit Step Size: 0.5 ℃, the actual temperature value was 45 * 0.5=22.5, which does not match our actual value

May I ask what is the reason for this situation? How should it be resolved?

Best Regards!

Iris