Tool/software:

Hi Team,

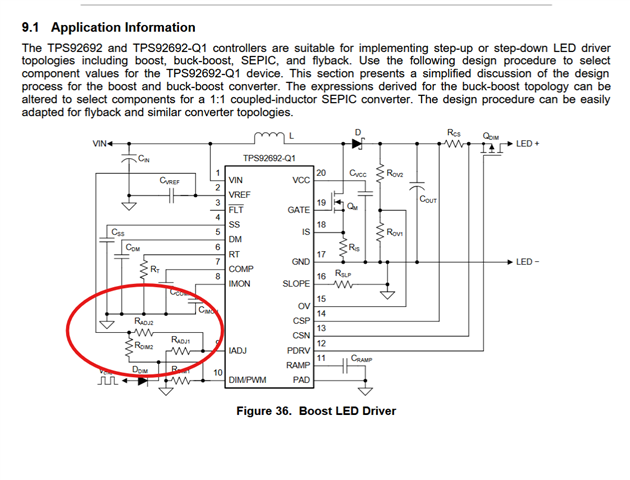

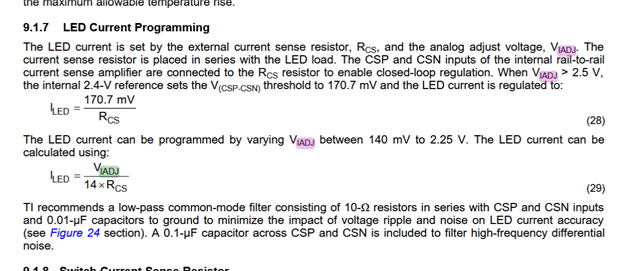

We are considering TPS92692 for one of our designs. The input is 9V-36V. The output current is expected to be around 10A at 50V.

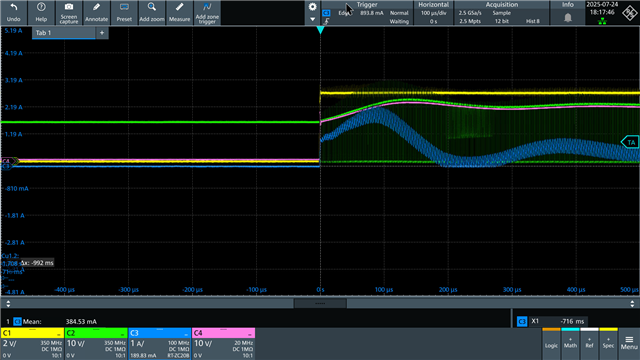

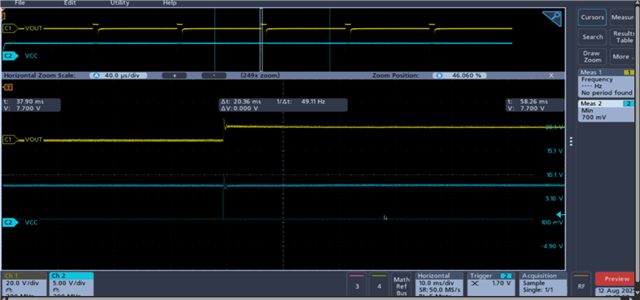

The PWM input is from 1Hz to 67Hz. The on-time for all of these is 1ms (fixed) and the off-time varies accordingly from 14ms to 999ms.

Ideally, we want the LEDs to turn on during high of PWM and turn off during low instantly. The DS gives a delay of 326ns which is acceptable.

We previously considered, TPS923655HMDMTR. But, 999ms low on PWM seems to disable the device. And there is a 5ms delay during start-up, which is not acceptable.

Is TPS92692 a suitable option for this application?

Thanks,

Jagan