Tool/software:

Hi

I want to use the battery cut off circuit in Ground path with 400V battery, please suggest the application circuit or driver circuit for that.

Configuration: Back-to-back MOSFETs with common drain or Common source.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Tool/software:

Hi

I want to use the battery cut off circuit in Ground path with 400V battery, please suggest the application circuit or driver circuit for that.

Configuration: Back-to-back MOSFETs with common drain or Common source.

Eswara,

Would the nominal voltage going into the switch be 400V or would there be a DC/DC converter somewhere bucking it down to 48V or 12V?

Best Regards,

Tim

Got it- in this case, one of the products from our solid-state relay team will be more applicable. I will assign this to that team and they will get back to you shortly.

Welcome to E2E by the way!

I want MOSFETs based solution in ground path. please suggest the driver circuit & Provide application note for this.

Hi Eswara!

We have a large selection of solid-state relays that use integrated MOSFETs or can be used to drive external MOSFETs, so we can still keep a MOSFET-based solution for this battery cutoff circuit. Here is a link to our portfolio: https://www.ti.com/power-management/power-switches/solid-state-relays/products.html

As far as your 400V battery application, a potential solution would be to use a TPS4141-Q1 for HV detection and a TPSI2140-Q1 for the switch. The TPS4141-Q1 would act as a voltage divider and output a scaled-down voltage. This output would be fed into a comparator (Vin) along with a reference voltage (Vref) that determines your lower threshold. If Vin<Vref, the comparator will output a logic high. This output should then be connected to the enable pin (EN) of the TPSI2140-Q1, closing the integrated switch and providing a path to ground when a logic high is passed. This should prevent over-discharging of the battery by cutting off the circuit when the battery voltage drops below the threshold, and using isolated devices ensures that the low-voltage components are protected from the high voltages present in the battery.

Let me know if I can clarify this example application or if you have any questions about our portfolio!

Thanks for support,

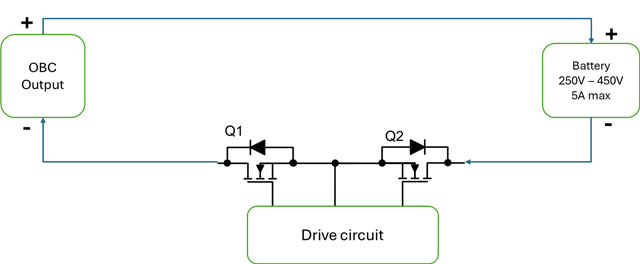

I need to protect the same MOSFETs for Reverse Polarity, Check the typical block diagram below,

Please suggest driver circuit for this application

Hi Eswara!

A similar setup could be used here for your reverse polarity protection circuit. If you need voltage sensing/detection in any location, I would suggest the TPS4141-Q1 + comparator setup I mentioned previously. As for the switches, I would suggest the TPSI2140-Q1 again if you wish to have integrated FETs. This part can take in a low-voltage enable signal from the detection circuit or from a microcontroller (if you want more manual switching) while protecting the auxiliary circuit from the high-voltage battery and OBC.

If you wish to have external switches, another option is to a gate driver to drive power MOSFETs like those shown in your diagram. A gate driver would interface with the detection circuit/microcontroller similarly to the TPSI2140-Q1, taking in a control signal on the enable pin to influence the output. For this, I would recommend the TPSI3100-Q1: an isolated switch driver that generates its own secondary bias supply and has dual isolated comparators for overcurrent protection. This provides a more robust solution as the secondary supply can be used for other components in the driver circuit that may need to exist on the high side, like inverting op-amps. Just as well, the added overcurrent protection will safeguard your high-voltage components with no additional cost/complexity overhead.

Hopefully this helps! If you give me more details about the intended operation of this circuit (i.e. when Q1/Q2 should be on or off, whether voltage detection is necessary, whether you want to use external FETs, etc.) I could try to provide a more in-depth solution.

Q1, Q2 will be controlled by Micro Controller, Micro controller will check polarity & short circuit diagnostics, if both are okay, MCU will the Enable.

Battery Voltage : 250V - 450V

Battery Current -- 5A

Eswara,

Do you already have a method in place for checking polarity diagnostics? If not, the TPS4141-Q1 could still provide an easy solution: it would take HV input across the battery/OBC terminals of interest and scale it down according to the divide ratio set by DIV1 and DIV0. Then, you could communicate the scaled output voltage signal (polarity included) to the microcontroller without causing any damage.

If you wish to have a more discrete solution, you could do something along the lines of using a power diode rated for the application, configured in an inverted direction such that it only conducts current when polarity is reversed. From here, you could connect the diode to a known-value resistor ladder to scale down the voltage before it is sent to the MCU. The purpose of this is to protect the MCU from high voltages while still communicating the magnitude and polarity of voltages/currents in the system. However, because both the diode(s) and resistors will contribute to undesirable power loss and heating, I still recommend the lower-power TPS4141-Q1 solution.

Once you have a diagnostic circuit, the switches are very simple to interface with the MCU: simply connect the controller to the enable pin of the TPSI2140-Q1 (or the TPSI3100-Q1 if you want to use external FETs). More information regarding enable voltage ranges, switching times, and other features can be found here for the TPSI2140-Q1 and here for the TPSI3100-Q1. Of course, feel free to browse the rest of our portfolio to see if one of our parts works better.

Please let me know if you have any questions about this solution or any of our products!