Other Parts Discussed in Thread: , TLV9302

Tool/software:

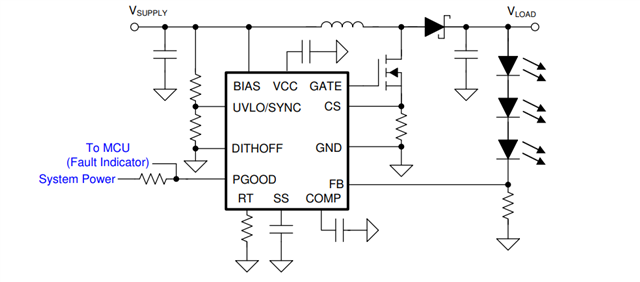

I am having a problem with my boost design. The circuit should be digitally controlled constant current step-up LED driver.

Conditions: Vin = 6 ... 9VDC

Maximum output power 6W (controlled and protected by the software)

Vout = 10 ... 60VDC output

Iout = DAC controlled 100 - 600 mA

Output power: 6W (100mA @ 60V, 600 mA @ 10V)

Osc. Freq. 100 KHz

When I set Iout below 190 mA (@10-12Vout), device regulates correctly. Anyway, with this output current efficiency is bad, about 75%.

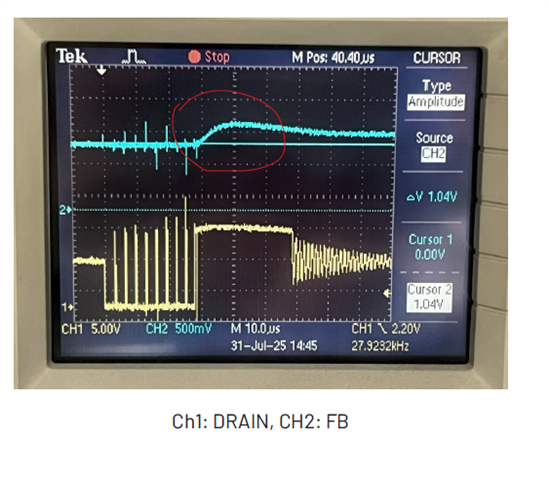

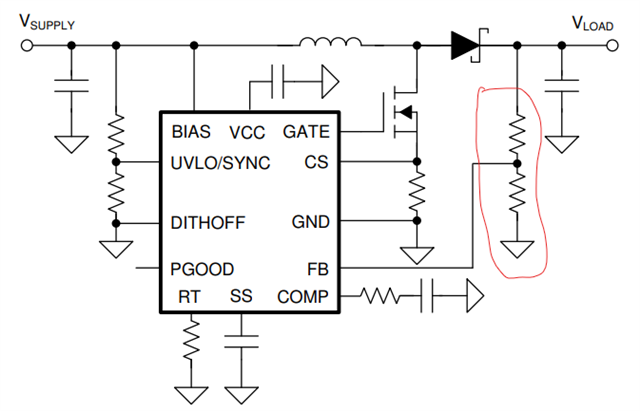

If I set 220 mA or more, device enters in burst mode. I tried all possibilities: modify FB filter, COMP filter, oscillator frequency, output capacitors, but nothing helps. In this case efficiency drops below 40% and inductor and mosfet heats abnormally.

The PCB layout is very good, 4 layers, device is WSON12 with exposed pad. All components top quality.no long tracks, everything very near.

What to do? The project is in the final stage and we are blocked here. URGENT, thank you.