Other Parts Discussed in Thread: TPS61165

Tool/software:

Hello,

I'm designing a Boost LED driver using the TPS923652, and I would like to confirm that my chosen switching frequency is safe with respect to the controller’s minimum off-time requirement.

Design specification:

-

VOUT: 25.6 V

-

VIN range: 6.0 V to 8.4 V (2S Li-ion)

-

Minimum off-time (datasheet): 100 ns

-

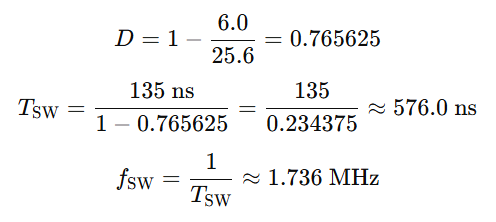

Design margin on Toff: +30% → 135 ns minimum used in calculations

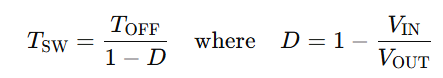

To ensure I'm within safe operating limits, I computed the required switching period from the off-time constraint using the formula:

Using the worst-case condition (highest duty cycle at VIN = 6.0 V):

So, to maintain a 135 ns minimum off-time, the maximum safe switching frequency should be ~1.74 MHz.

With Rfset = 18kOhm I choose 1.5MHz.

My questions are

- Can you confirm that this reasoning is valid and that the calculations are correct?

- Is there any additional timing margin you would recommend (e.g., more than 30%) to account for internal tolerances or variations?

Thank you for your support.

Best regards,

Thomas