Tool/software:

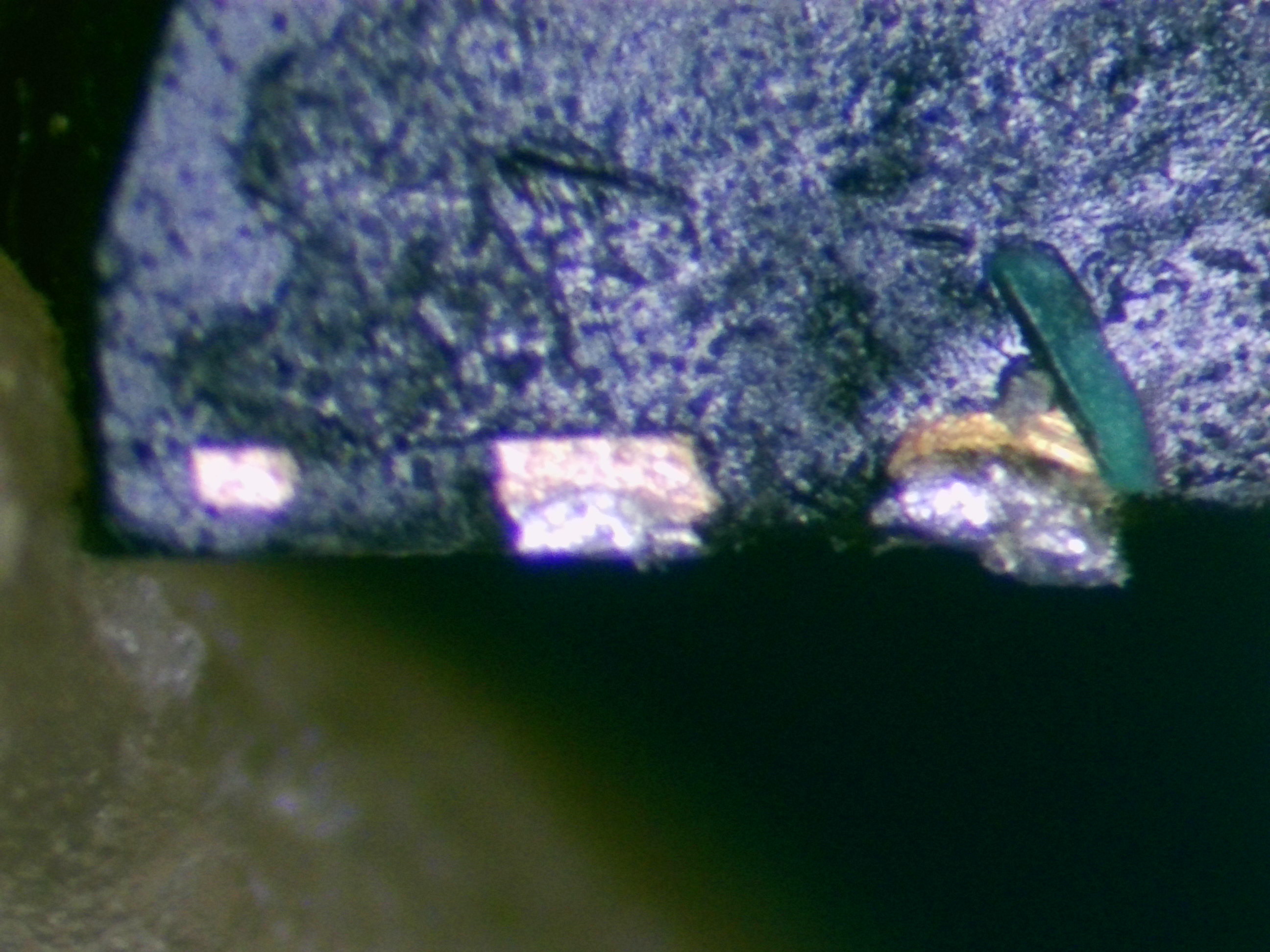

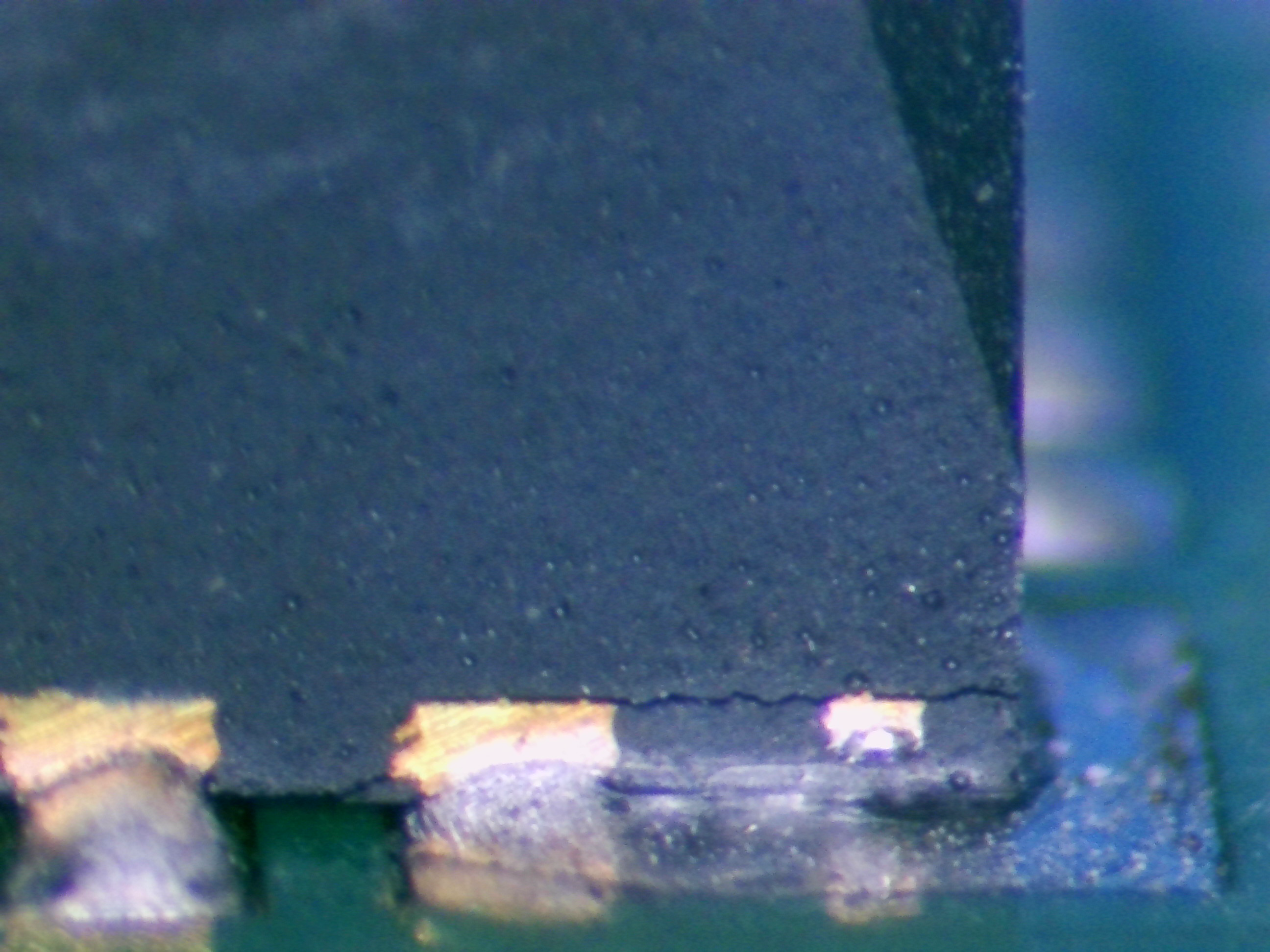

Several TPS84A20RVQT devices have failed in the field with low output voltage. We have found some devices have hairline cracks between the pin 7 metalization and the package (see images below) and others have at a failed solder joint at pin 7. Is TI aware of any cause for these types of failures?