Tool/software:

Hi,

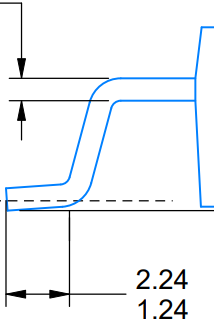

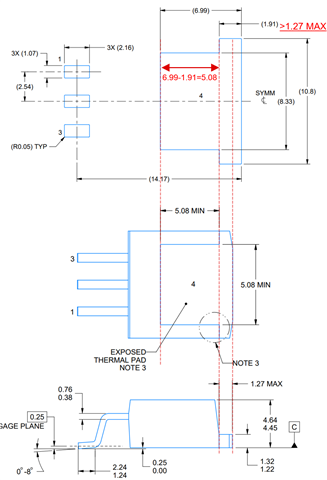

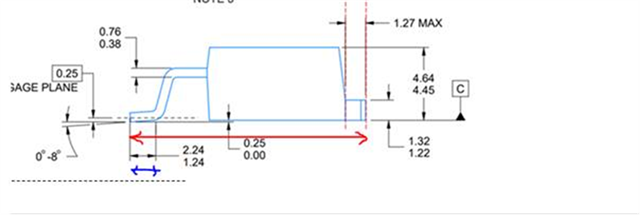

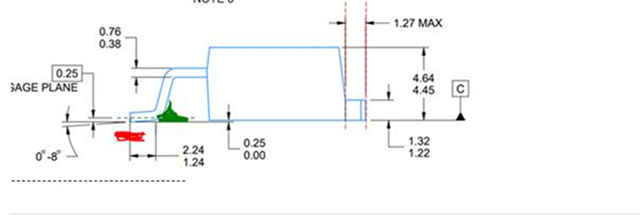

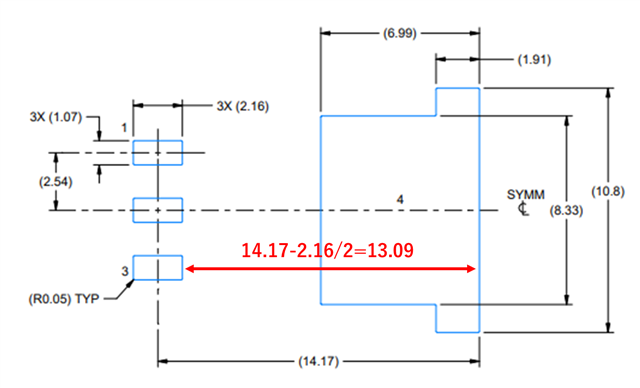

I have a question about the land distance of the TO-263 package. Please tell me the recommended distance of the red line in the data sheet below.

The data sheet states that the distance between the pin and the PAD is 13.09mm. However, in the actual IC, this distance was about 12mm. Therefore, the back fillet of the solder is not formed during mounting.

Best Regards,

Nishie