Other Parts Discussed in Thread: BQSTUDIO

Tool/software:

Tool/software:

Hello,

This question has been assigned and will be reviewed when possible.

Thank you,

Alan

Hello,

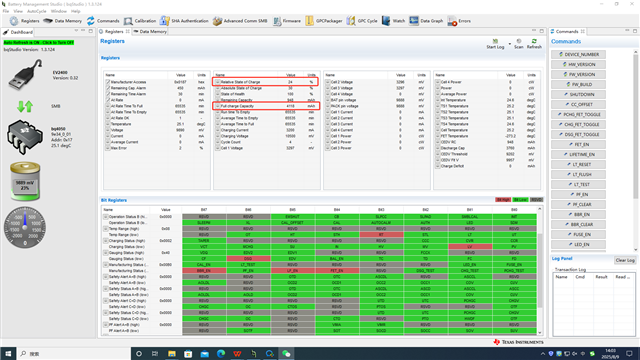

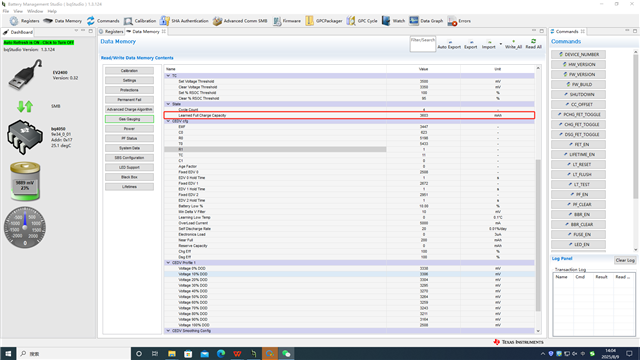

The CEDV gauging will update FCC when the EDVx thresholds are reached. The TRM states on section 6.3 the new FCC updates after:

FCC (new) = DCR (final) = DCR (initial) + Measured Discharge to EDV2 + (FCCx Battery Low%)

Do you know if what is the EDV2 value when they got the FCC jump?

The key here is to know if the device was in qualified discharge event. The TRM states it needs multiple conditions to meet this:

I looked into your gg file closer.There seems to be multiple protection events on this part. Did you test this part before? I also see a permanent fail (PF) of voltage on CELL1 of ~1V which is very low. If the voltage of one the cells is getting too low, it might be triggering the qualified discharge event. However, the part needs to remain on that EDV2 + ~256 mV voltage for a period of time.

Can you elaborate what was the state of the gauge and the battery pack during "static"?

Is this issue repeatable? If so, can you capture a log from Bqstudio I can take a look closer?