Tool/software:

Tool/software:

Hi,

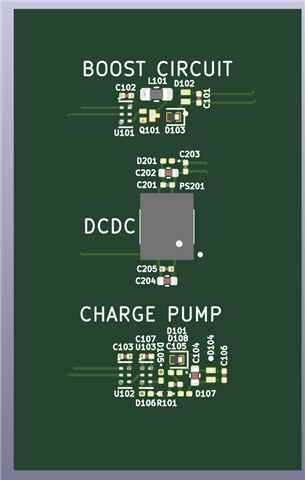

I'm designing a compact FOC controller with LMG2100R026

Board space is at a premium.

I would also like to maximize acceptable voltage at the motor, which means having, at time, high duty cycle.

My understanding is that, for "normal conditions", the maximum duty cycle is roughly 67% (100nF bootstrap capacitor, 100mA charging current, 100kHZ operating frequency, 8mA operating current)

I'm looking for ways to keep the bootstrap capacitor topped up.

I understand there are 3 possibilities:

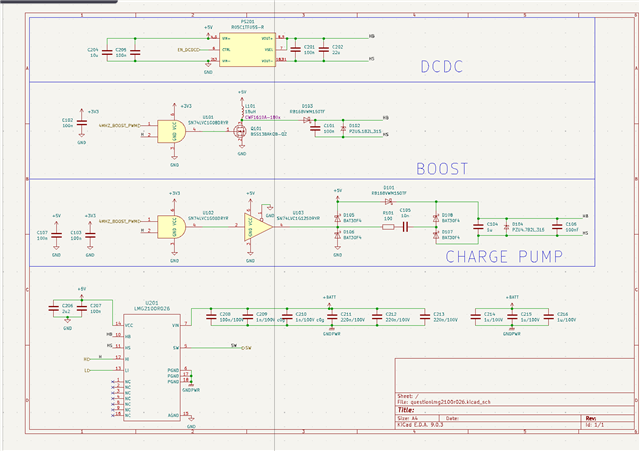

- Use of a low capacitance isolated DCDC.

An affordable option is R05C1TF05S-R or MIE1W0505BGLVH, but it is somewhat bulky

I could also use an ILDC12, but they are a bit pricey (like, same price as LMG2100R026 or so), and don't have great voltage regulation (4.5->5.5V)

- Use of a charge pump.

This has several limits. Besides polluting my 5V rail with each swing of the output (thanks to the high V/ns of LMG2100), it has quite low efficiency when VBUS = 90V

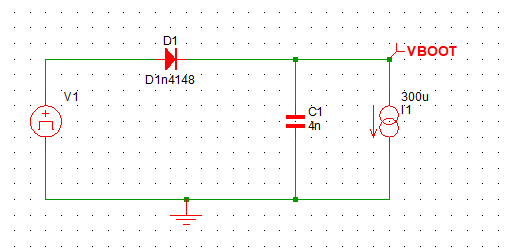

- Use of a boost circuit.

This would be my preferred solution. No capacitive coupling with my 5V rail, modularity, compactness etc.

Here are 3 options, based on values I calculated.

Note : while and-gates are not necessary, they prevent wasting energy pumping into a low bridge.

Is there a reason _not_ to use the boost circuit ?

Thanks