Tool/software:

Hi Teams,

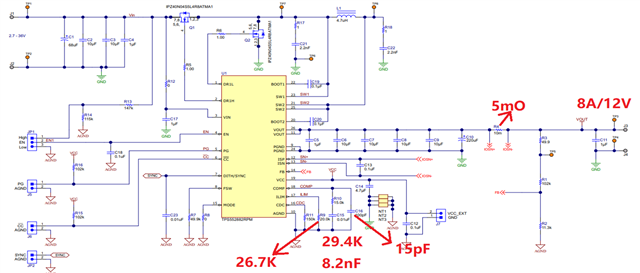

Can the TPS552882 support the following input and output conditions? Vin 9~36V, Vout 12V, Iout 8A.

I tried simulating it using WEBENCH but couldn't get any results, thanks.

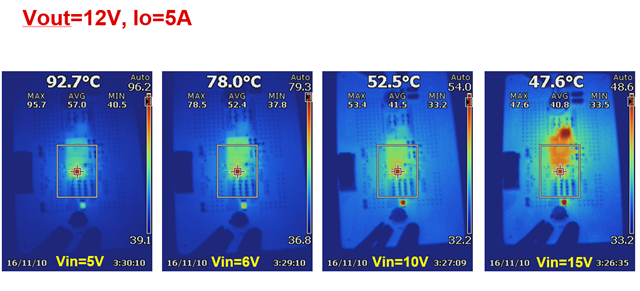

Otherwise, I found that when using Webench with Vin 9V and Vout 12V 8A, it shows that the IC temperature is too high.

However, we tested with the EVM and the actual temperature was normal (50-60°C). Could you please help confirm if there is any risk in this situation?